+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

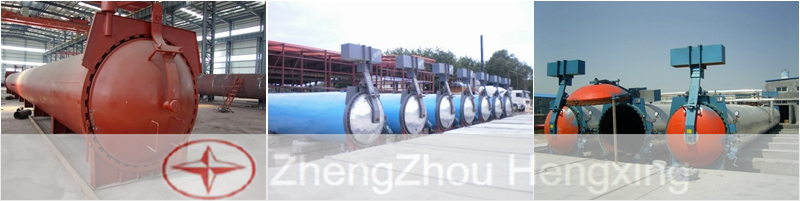

Autoclave

Production: 30000-300000 m³/year

Max. diameter: 6m

Max. length: 60m

Raw materials: Cement, lime, sand( or fly ash), gypsum, aluminium powder, water.

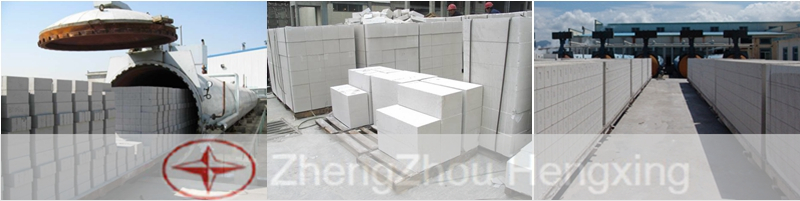

Application: The autoclave is applicable for curing the cut body under high temperature and high pressure, and is also applicable for curing the autoclaved brick under high temperature and high pressure.

MOQ :

1

Introduction of Autoclave

Autoclave is large steam equipment, it is applicable for curing the cut body under high temperature and high pressure, and is also applicable for curing the autoclaved brick under high temperature and high pressure. The working medium is saturated water vapor.

The main parts are made by autoclave body, cover, hand-operated reducer, safe blocking device, support saddle, valve meter etc. The body is a principle and the cylindrical device made of steel. The cover is made of a whole piece of pressed 16MnR steel board, and the flanges of cover and body adopt a whole piece of forged and processed 16Mn steel board.

Autoclaved kettle application is very extensive, a large number of applications in aerated concrete block, concrete pipe pile, lime-sand brick, fly ash brick, microporous calcium silicate board, insulation asbestos board, high-strength gypsum building materials, such as autoclaved curing.

Our company can manufacture all kinds of autoclaves according to requirements of users to meet the demands of application.

Advantages of Autoclave:

1. Patented technologies. Many parts of autoclave such as Automatic Hydraulic Opening Door (Process and Device), Cutting Kettle Tooth, Pressure Drainage Device of Autoclave and Electrical Safety Interlock Device of Autoclave are patented and tested technologies.

2. Material:

a. Special die double scale container board of Q345R-GB713.

b. 16MnⅡlevel of making flange forging

c. Adopt φ133×25 to make a tube of DN100, and the material is 20-GB9948.

3. Process:

a. After welding kettle door, it must proceed annealing heat treatment.

b. Polish toothed cutter of flange of the autoclave body, and carry out magnetic particle testing.

c. Use double scale container board, and ensure the longitudinal joint of each section.

d. Carry out the physical and chemical test (stretch, impact), ensure its strength.

e. Welds are 100% X-ray detection, then carry out a hydraulic test of 2.1MPa after passing. The whole process is completely inspected by CSEI factory inspection, and leave factory after stamp and signature.

Selection principle of Autoclave

Autoclave belongs to low cycle fatigue pressure vessel. So the right choice of main pressure part material is especially important. Selection principles have the following five:

1. According to service conditions of vessels, such as design temperature (design pressure, medium characteristic, operating feature). Selected material should have enough strength. This is necessary for autoclave to bear all kinds of loads.

2. Good toughness. If material toughness is not good, it will directly affect service life of autoclave which is considered by low cycle fatigue stress. This is one of the main reasons which cause brittle failure of the autoclaves.

3. Good process and weldability. In order to improve weldability, we should use low phosphorus sulfur of high-quality steels which carbon content is less than 0.25%. It needs better cold heat processing.

4. Good corrosion resistance.

5. Material price is reasonable and source of goods is ample.

Technical data

|

Model |

Highest |

Working |

Design |

Working |

Working |

Dimension |

|

Ø2x21 |

1.4 |

1.3 |

198.34 |

194.13 |

Saturate steam |

22.12x26x2.973 |

|

Ø2.5x31.5 |

1.6 |

1.5 |

203 |

200 |

Saturate steam |

33.2x3.2x4 |

|

Ø2.68x39 |

1.6 |

1.5 |

203 |

200 |

Saturate steam |

40.65x3.46x4.25 |

|

Ø2.85x26 |

1.65 |

1.5 |

205 |

205 |

Saturate steam |

27.4x3.595x4.504 |

|

Ø2.85x39 |

1.65 |

1.5 |

205 |

205 |

Saturate steam |

40.4x3.595x4.504 |

If you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727