+86-137-8347-1727

+86-137-8347-1727

Products List

Hot Products

Impact Stone Crusher Feed opening: 820x700-1600x2080mm Feeding size: ≤500mm Application: All kinds of ore crushing, railways, highways, energy, cement, chemicals, construction and other industries. Processible Materials: Side length from 100 to 500 mm below the material,1

PE Jaw Crusher Feed opening: 150×250-300×1300mm Feeding size: 125-250mm Production: 1-2200 t/h Application: Metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry etc. Processible Materials: lime1

Cone Crusher Cone diameter: 600-2200mm Feeding size: 35-300mm Production: 12-1000t/h Application: Metallurgy, building materials, road construction, chemical and silicate industry. Processible Materials: Barite, marble, calcite, kaoline, coal, gypsum, concrete, r1

Active Lime Production Line

Active lime plant is also called quick lime plant, lime production plant and limestone production line. It is equipped with sophisticated equipment, which has stable and reliable operation. The configured lime kiln not only can process limestone, dolomite, kaolin and cement, but also can be used in refractory material industry, magnesium oxide, alumina, zinc oxide, coke industry, etc.

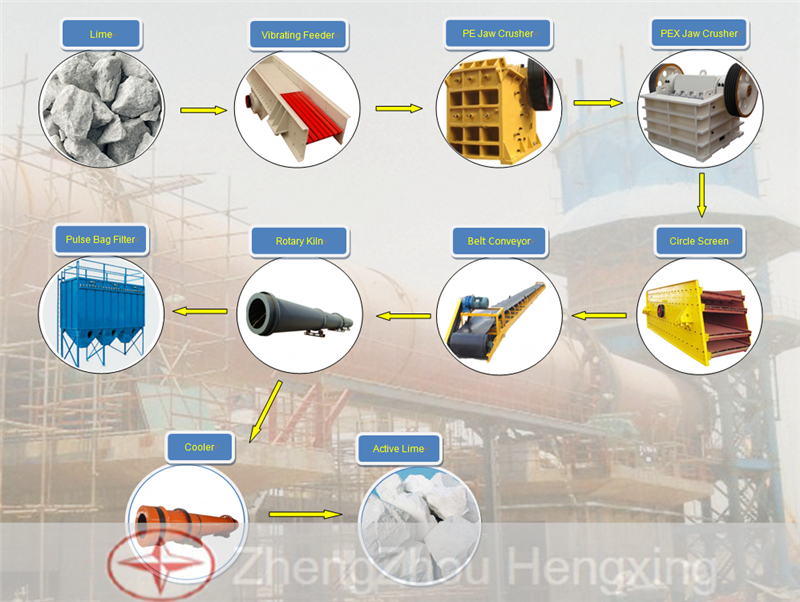

Active Lime Production Line Flow And Description

1. Limestone feeding to PE jaw crusher for primary crushing by vibrating feeder.

2. After primary crushing the limestones then conveyed to PEX jaw crusher for secondary crushing.

3. 10-50mm qualified limestone are fed to screening equipment. After screening, the limestone will be transported to the top silo of preheater by inclined belt conveyor.

4. Limestone are fed from top silo to preheater through feeding chute. At the meantime, the hot air from rotary kiln will preheating the limestone to more than 1000℃ and also can partially decomposed. Preheated limestone are pushed into kiln inlet by hydraulic pusher for calcination.

5. Then discharged into vertical cooler after calcination at rotary kiln. The cooling air blows by fan can cool down the temperature of material to room temperature +60℃ and then discharged out of vertical cooler.

6. At the same time the hot air will flow into Cyclones Dust Collector for primary dust collecting. After bigger size dust are collected, the waste air will flow into bag filter for secondary dust collecting. The emission dust concentration is less than 50mg/m³。

7. After discharging from vertical cooler, active lime will be transported to lime silo by apron conveyor, bucket elevator and belt conveyor.Temperature of hot air from rotary kiln can be reduced to 250℃ after heat exchange with limestone inside the preheater.

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727