+86-137-8347-1727

+86-137-8347-1727

Products List

Hot Products

Impact Stone Crusher Feed opening: 820x700-1600x2080mm Feeding size: ≤500mm Application: All kinds of ore crushing, railways, highways, energy, cement, chemicals, construction and other industries. Processible Materials: Side length from 100 to 500 mm below the material,1

PE Jaw Crusher Feed opening: 150×250-300×1300mm Feeding size: 125-250mm Production: 1-2200 t/h Application: Metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry etc. Processible Materials: lime1

Cone Crusher Cone diameter: 600-2200mm Feeding size: 35-300mm Production: 12-1000t/h Application: Metallurgy, building materials, road construction, chemical and silicate industry. Processible Materials: Barite, marble, calcite, kaoline, coal, gypsum, concrete, r1

Iron ore beneficiation and iron concentrate processing and utilization iron ore beneficiation method

The iron minerals of industrial value are mainly: magnetite, hematite, pseudo-hematite, limonite and siderite. except magnetite is strong magnetic materials , others are weak magnetic minerals.

iron ore resources are rich in China, iron ore types are: 1) magnetite ore; 2) multi-iron mineral iron ore (magnetite-hematite ore. magnetite-siderite ore, mirror iron ore-Ling Iron ore-hematite ore, etc.; 3) vanadium-containing titanium magnetite ore; 4) sulfide-containing polymetallic iron ore; 5) polymetallic iron ore containing sulfide, phosphorus or rare earth; 6) Braided hematite ore (hematite - siderite ore, siderite ore, etc.).

Strong magnetic magnetite ore

1.Single magnetite ore

Since most of the ore is a ferromagnetic magnetic mine, and the ore composition is simple, it is often extract by weak magnetic separation.

2.Multi-metal magnetite ore

It is mainly composed of sulfide magnetite ore and apatite magnetite ore. Generally, a weak magnetic separation and flotation combined process is adopted, that is, iron is recovered by weak magnetic separation, and sulfide or apatite is recovered by flotation.

Weak magnetic iron ore

1.Single weak magnetic iron ore

Including hematite ore, siderite ore, limonite ore and red iron (mirror iron) siderite ore. These weak magnetic iron ore are often referred to as "red mines." The ore dressing methods of the red ore have strong magnetic separation, flotation, gravity selection, roasting magnetic separation and the combined use of these methods.

2.Polymetallic weak magnetic iron ore

Hematite ore or siderite ore mainly containing phosphorus or sulfide. Such ores are generally gravity selection, floated, strongly magnetically selected, or combined with each other to recover iron minerals, and phosphorus or sulfide is recovered by flotation.

Magnetite Ore - Hematite - Siderite

1.Single Magnetite Ore - Hematite - Siderite

Mainlyhematite -magnetite ore and magnet-pyrite ore. The methods for selecting such ores are as follows: 1) weak magnetic separation and gravity selection, flotation, and strong magnetic separation, that is, recovery of magnetite by weak magnetic separation, recovery of weak magnetic iron by gravity selection, flotation or strong magnetic separation ; 2) Magnetization roasting magnetic separation or combine with other methods, similar to magnetization roasting of single weak magnetic iron ore, but in the parallel flow of magnetization roasting magnetic separation and other beneficiation methods, the powder ore is Weak magnetic separation combined with other methods; 3) selective flocculation desilting method.

2. Multi-metal Magnetite Ore - Hematite - Siderite

The main types of such ores are: Sulfide iron ore and phosphorus, sulfur or rare earth iron ore. The ore dressing method of this type of ore is more complicated in iron ore beneficiation. Generally, the combined process of weak magnetic separation and other methods is adopted, that is, magnetite is recovered by weak magnetic separation; recover weak magnetic materials by gravity selection, flotation or strong magnetic separation.

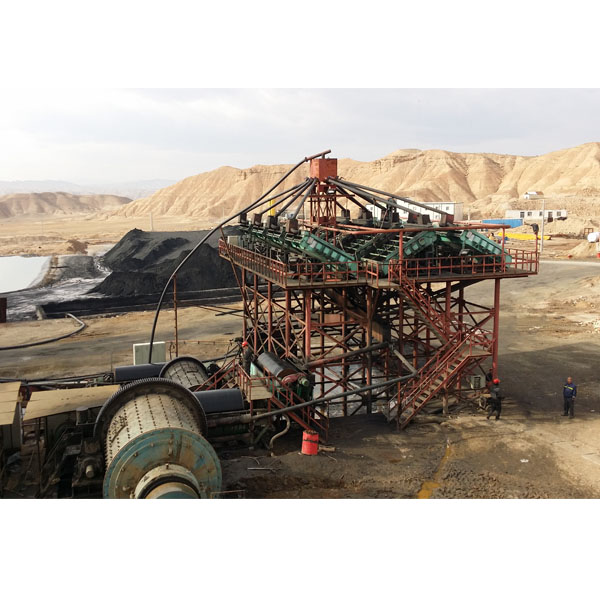

Zhengzhou Hengxing Heavy Equipment Co.,Ltd Supply various models of beneficiation equipment ,welcome to send inquiry and visit our factory .

Previous:

Double roller Crusher StructureNext:

Machine For Cleaning Sand +86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727