+86-137-8347-1727

+86-137-8347-1727

Products List

Hot Products

Impact Stone Crusher Feed opening: 820x700-1600x2080mm Feeding size: ≤500mm Application: All kinds of ore crushing, railways, highways, energy, cement, chemicals, construction and other industries. Processible Materials: Side length from 100 to 500 mm below the material,1

PE Jaw Crusher Feed opening: 150×250-300×1300mm Feeding size: 125-250mm Production: 1-2200 t/h Application: Metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry etc. Processible Materials: lime1

Cone Crusher Cone diameter: 600-2200mm Feeding size: 35-300mm Production: 12-1000t/h Application: Metallurgy, building materials, road construction, chemical and silicate industry. Processible Materials: Barite, marble, calcite, kaoline, coal, gypsum, concrete, r1

AAC Block Making Production Line

AAC Blocks (Autoclaved Aerated Concrete Blocks) also known as Autoclaved Cellular Concrete(ACC), autoclaved lightweight concrete(ALC) is a lightweight, precast, foam concrete building material which provides blocks structure, insulation, fire and mold resistance. It can be used for commercial, industrial and residential construction.

AAC Blocks are produced by using the common materials like sand, lime, cement and water, and a small amount of rising agent (Foaming agent). After mixing and molding, the blocks are sent into the autoclave, after steam curing, we get unique lightweight AAC Blocks.

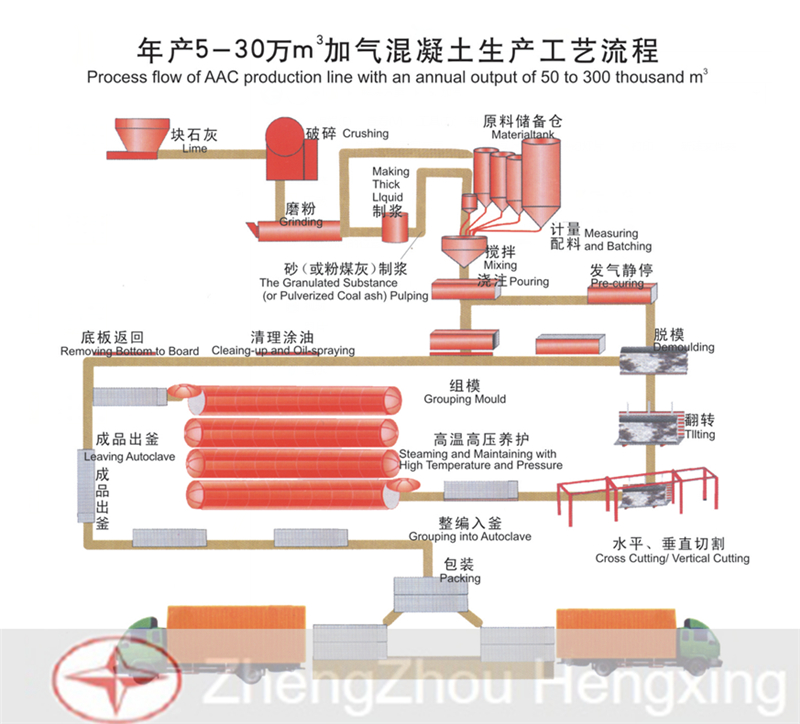

AAC Block Making Production Line Flow And Description

1. Crushing lime to smaller size.

2. Griding the small lime to powder.

3. Dose and match measured raw materials.

4. After distributing, pour and mix these materials in the mixer to make slurry.

5. Through thoroughly mixing, the slurry is poured to mould.

6. After pre-curing under a certain temperture and time, the block would reach a certain hardness prepare for cutting.

7. Tilting hoister would turn over 90 degree of mould, then open the mould and separate it from block, and take the block woth side plate to cutting cart.

8. Concrete blank then be cut on the cutting machine in six sides, the blocks be cut through the cutter firstly of two vertical sides of block.

9. Secondly the horizontal cutting, finally the vertical cutting.

10. After cutting, the block is hanged to trolly with side plate by semi-finished product hoister. Organizing the cut blocks and put them into autoclave.

11. Hardending the blocks under certain temperture and pressure.

12. Take finished products out of autoclave.

13. The finished product hoister take the finished product to stock shield. Packed for loading.

14. The side plate return back by side plate roller and would be organized with open mould

15. Clean the mould and preparing for next pouring

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727