+86-137-8347-1727

+86-137-8347-1727

Products List

Hot Products

Impact Stone Crusher Feed opening: 820x700-1600x2080mm Feeding size: ≤500mm Application: All kinds of ore crushing, railways, highways, energy, cement, chemicals, construction and other industries. Processible Materials: Side length from 100 to 500 mm below the material,1

PE Jaw Crusher Feed opening: 150×250-300×1300mm Feeding size: 125-250mm Production: 1-2200 t/h Application: Metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry etc. Processible Materials: lime1

Cone Crusher Cone diameter: 600-2200mm Feeding size: 35-300mm Production: 12-1000t/h Application: Metallurgy, building materials, road construction, chemical and silicate industry. Processible Materials: Barite, marble, calcite, kaoline, coal, gypsum, concrete, r1

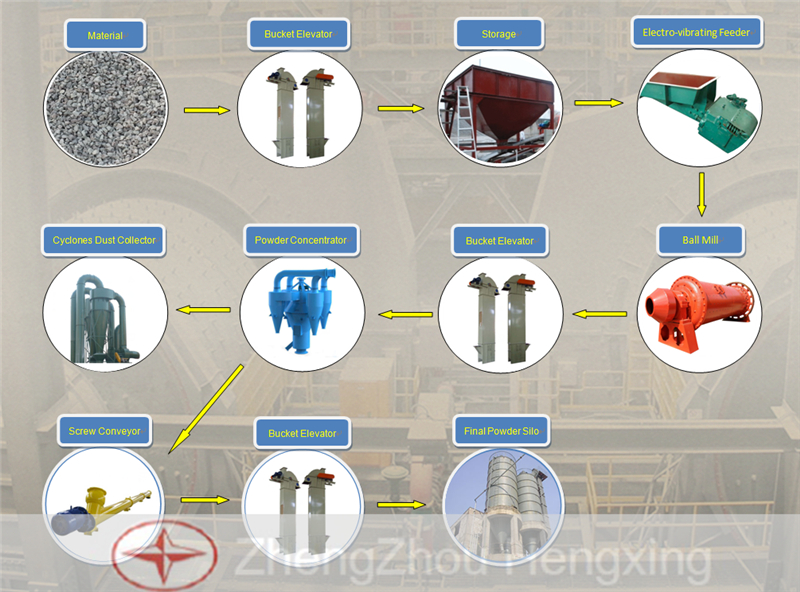

Powder Milling Process

Powder grinding plant can be applied to the power processing of the feldspar, calcite, talc, barite, fluorite, rare earth, marble, ceramics, bauxite, manganese, phosphate rock, red iron oxide, quartz sand, cement clinker, activated carbon, clay, coal gangue, gypsum, silicon carbide, refractory and other humidity less than 6% of the non-flammable, non-explosive mineral materials.

The whole structure of our powder making plant or powder making line is mainly composed of ball mill, powder classifier, cyclone dust collector, jaw crusher, bucket elevator machine, hopper, screw conveyor, electromagnetic vibrating feeder and distribution cabinet.

Powder Milling Process Flow And Description

1. After being crushed by jaw crusher, the large bulk materials will be sent to the storage hopper through bucket elevator.

2. Then evenly fed into the ball mill to grind by the electro-vibrating feeder.

3. The grinded powder will be brought by bucket elevator to powder classifier.

4. The qualified fineness powers will enters into the large cyclone collector with the air stream and then discharged by the screw conveyor.

5. At last, the powder transferred to final powder silo by bucket elevator.

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727