+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

PE Jaw Crusher

Feed opening: 150×250-300×1300mm

Feeding size: 125-250mm

Production: 1-2200 t/h

Application: Metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry etc.

Processible Materials: limestone, pebble, calcite, granite, quartz, concrete, dolomite, basalt, iron ore, limestone, construction waste, etc.

Brand:

HengxingMOQ :

1

Introduction of Jaw crusher

Jaw Crushers are often used as primary crushers and are perhaps the most popular crusher worldwide. These compressive crushers are suitable for most type of stone material.

Materials are fed into the opening of the jaw crusher by a vibrating feeder. The eccentric rotating drive shaft causes the movable jaw to oscillate crushing the aggregate against a fixed jaw.

Jaw crushers are run on belt drives driven by an electric motor or diesel engine. Jaw crushers are used extensively throughout the aggregate and mineral processing industry.

Jaw Crusher has the characteristics of large breaking ratio, uniform product end size, simple structure, reliable operation, easy maintenance, low operating costs and so on. We can specifically design jaw crusher units to meet your particular crushing needs.

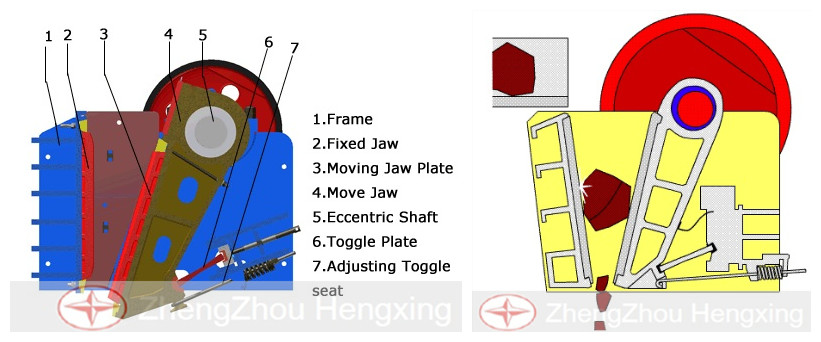

Working principle of jaw crusher:

Stone jaw crusher working part is two jaw plate, namely fixed jaw plate and moving jaw plate. Between the two jaw plate, there is a crushing cavity.

The motor transmits power through belt and belt pulley, drives the moving jaw plate to surround the eccentric shaft to the periodic motion.

The angle between fixed jaw plate and moving jaw plate increases when moving jaw plate moves up, which makes the moving jaw get closer to the fixed jaw.

The material is squeezed, rubbing, grinding and other multiple crushing. When the moving jaw plate move off the fixed jaw plate, the crushed material has been discharged by gravity from the discharge mouth.

2. Superior steel plate welded by CO2 gas shielded welding and annealed to be durable.

3. The crushing chamber is deep and without dead zone, increases the capacity and the output. Can complete the crushing work of large-sized limestone.

4. Stable running solves the problem of high operation rate and little maintenance time caused by low output of limestone crusher.

5. Big ratio of crushing, high productivity.

6. Less electricity needed, long Life, low noise, less dust, cost effective.

|

Model |

Size of Feed Opening(mm) |

Max Feed Size (mm) |

Discharge Range Opening (mm) |

Capacity (t/h ) |

Motor Power(kw) |

Weight (t) |

|

PE-150x250 |

150x250 |

125 |

10-40 |

1-3 |

5.5 |

0.81 |

|

PE-150x750 |

150x750 |

125 |

10-40 |

5-16 |

15 |

3.8 |

|

PE-250×400 |

250×400 |

210 |

20-60 |

3-13 |

15 |

2.8 |

|

PE-400×600 |

400×600 |

340 |

40-100 |

10-35 |

30 |

7 |

|

PE-500×750 |

500×750 |

425 |

50-100 |

25-60 |

55 |

12 |

|

PE-600×900 |

600×900 |

500 |

65-180 |

30-85 |

55- 75 |

17 |

|

PE-750×1060 |

750×1060 |

630 |

80-180 |

72-150 |

110 |

29 |

|

PE-800×1060 |

800×1060 |

680 |

100-200 |

85-143 |

110 |

29.8 |

|

PE-870×1060 |

870×1060 |

750 |

170-270 |

145-235 |

110 |

29.2 |

|

PE-900×1060 |

900×1060 |

780 |

200-290 |

170-250 |

110 |

33 |

|

PE-900×1200 |

900×1200 |

780 |

95-225 |

100-240 |

110 |

50 |

|

PE-1000×1200 |

1000×1200 |

850 |

195-280 |

190-275 |

110 |

57 |

|

PE-1200×1500 |

1200×1500 |

1020 |

150-300 |

250-500 |

160 |

100.9 |

|

PEX-150×750 |

150×750 |

120 |

18-48 |

5-16 |

15 |

3.8 |

|

PEX-250×750 |

250×750 |

210 |

25-60 |

8-22 |

22 |

5 |

|

PEX-250×1000 |

250×1000 |

210 |

25-60 |

10-32 |

30-37 |

7 |

|

PEX-250×1200 |

250×1200 |

210 |

25-60 |

13-38 |

37 |

8.7 |

|

PEX-350x750 |

350x750 |

280 |

30-80 |

16-55 |

30 |

6.1 |

|

PEX-300×1300 |

300×1300 |

250 |

20-90 |

10-65 |

75 |

11.6 |

Previous:

Cone CrusherNext:

Heavy Hammer CrusherIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727