+86-137-8347-1727

+86-137-8347-1727

Products List

Hot Products

Impact Stone Crusher Feed opening: 820x700-1600x2080mm Feeding size: ≤500mm Application: All kinds of ore crushing, railways, highways, energy, cement, chemicals, construction and other industries. Processible Materials: Side length from 100 to 500 mm below the material,1

PE Jaw Crusher Feed opening: 150×250-300×1300mm Feeding size: 125-250mm Production: 1-2200 t/h Application: Metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry etc. Processible Materials: lime1

Cone Crusher Cone diameter: 600-2200mm Feeding size: 35-300mm Production: 12-1000t/h Application: Metallurgy, building materials, road construction, chemical and silicate industry. Processible Materials: Barite, marble, calcite, kaoline, coal, gypsum, concrete, r1

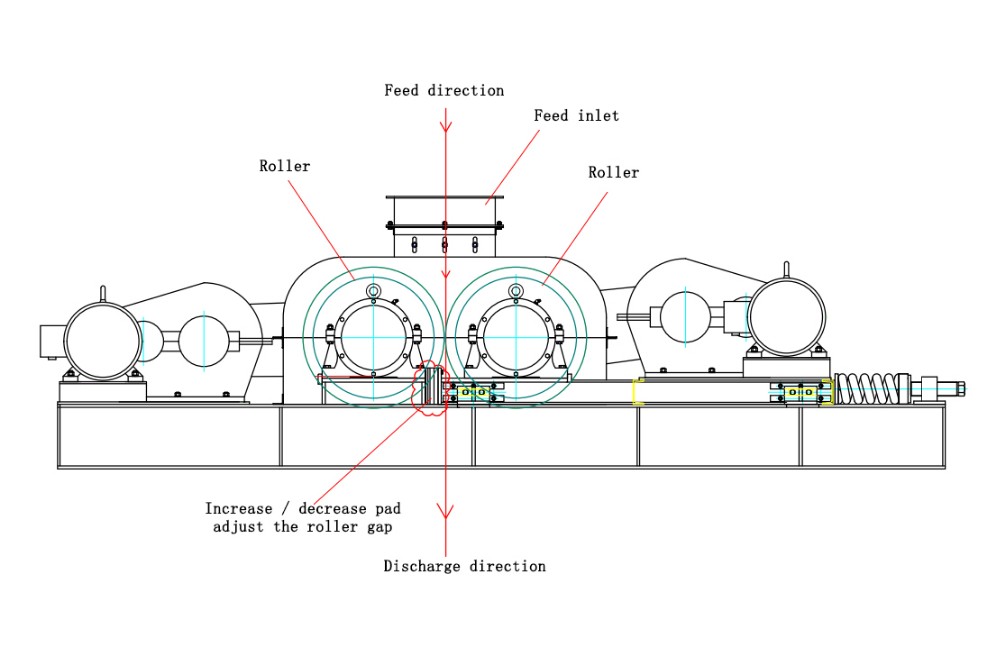

Double roller Crusher Structure

The double roller crusher ( smooth surface) consists of a crushing roller, an adjustment device, a spring safety device, drive devie, and a frame.

Crushing roller

It is a parallel rotating roller on the horizontal axis which is the main working mechanism of the crusher. The bearing of one of the rollers is movable, the bearing of the other roller is fixed, and the crushing roller is composed of a shaft, a hub and a roller skin. The roller shaft is keyed to the hub of the conical surface, the roller skin is fixed to the hub, and the three conical arc irons are used to fix them together by bolt nuts. Since the roll skin is in direct contact with the ore, it needs to be replaced from time to time, and it is generally made of high-manganese steel or special carbon steel (chrome steel, chrome-manganese steel, etc.) with good wear resistance.

Adjustment device

The adjusting device is used to adjust the size of the gap between the two crushing rollers (the discharge port), which is controlled by increasing or decreasing the number of gaskets between the two roller bearings, or by adjusting with a worm gear adjusting mechanism. Broken product size.

Spring safety device

It is a very important part of the roller crusher. The degree of spring tension plays an important role in the normal operation and overload protection of the crusher. When the machine is working normally, the pressure of the spring should balance the force generated between the two rollers to maintain the gap between the discharge ports and make the product evenly uniform. When the crusher enters a non-broken object, the spring should be compressed, forcing the movable crushing roller to move laterally, and the width of the discharge opening is increased to ensure that the machine is not damaged. After the non-broken object is removed, the spring returns to its original state and the machine works as usual. During the working process of the crusher, the safety spring is always in a vibrating state, so the spring is easily fatigued and damaged, and must be inspected frequently and regularly.

Drive Device

The motor drives the two crushing rolls to rotate in opposite directions by a V-belt (or a gear reduction device) and a pair of long-toothed gears. The gear is a special standard long tooth. When the crusher enters a non-broken object, the distance between the two rollers will change. At this time, the long tooth gear can still ensure normal meshing. However, such long-toothed gears are difficult to manufacture, often stuck or broken during work, gear repairs are also difficult, and noise is high during operation. Therefore, the long-toothed gear transmission is mainly used for a two-roller crusher with a low number of revolutions, and the peripheral speed of the surface of the roller is less than $m%. A crusher with a higher number of revolutions (circumferential speed greater than & m% seconds) often uses a separate motor to drive the two rollers to rotate, which requires the installation of two motors (or two sets of reduction gears), which is more expensive.

frame

The frame is usually cast in cast iron or welded or riveted in profiled steel. The frame structure must be strong.

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727