+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Mould, Mould Base Plate

Production: 30000-300000 m³/year

Raw materials: Cement, lime, sand( or fly ash), gypsum, aluminum powder, water.

MOQ :

1

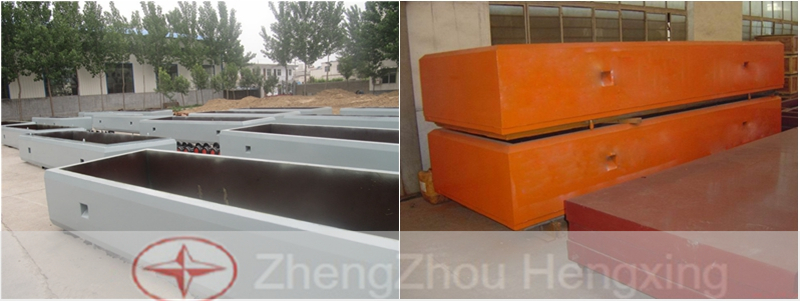

Introduction of mould, mould base plate

Mould is one of the main ancillary equipment in the production of aerated concrete. The casting machine pours the well-proportioned and mixed materials into the mould, solidifying and expanding. After curing, mould, which can be cut.

The hardening car organizes the body and bottom plate into groups and carries them into an autoclave for steam curing. Adopt 12# trough steel welded together, combined with bottom board and mould casing, operation smooth and light.

Application of mould, mould base plate

In the third stage of AAC production line, we need use mold/mould and side plate, for the AAC block casting and maintenance.

Materials slurry can be put into the combining of the mould and the bottom surface plate. After curing and foaming it can be solidified into the blank.

The bottom surface plate can bear the blank which shall be cut by the cutting machinery, and fed into the autoclave to be hardened together with the autoclaved car/steaming larry.

Technical data

Size

Dimension(mm)

4m

4050×1240×650

4.2m

4250×1240×650

4.8m

4850x1240x650

6m

6050×1540×650

Previous:

Ferry Push CarNext:

Hardening CarIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727