+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Rotary Kiln

Production: 180-1000(t/d)

Specification: Φ2.5×40m-Φ6.0×95(m)

Application: Lean iron ore magnetizing roasting, cement making industry, chromium and nickel-iron oxidizing roasting in steel plants of metallurgy

Processible Materials: Dolomite, active lime, cement clinker, and bauxite.

MOQ :

1

Introduction of rotary kiln

Rotary kiln refers to the rotating furnace, it belongs to the building material equipment. According to the difference of the processing material, it can be divided into cement kiln, metallurgy & chemical kiln and lime kiln.

The rotary kiln is the key equipment in cement industry for calcinating clinker. lt is also used in metallurgy and chemical industries, which is suitable for non-ferrous metals, concentrate, coarse ore, intermediate, lime, dolomite, etc.

The kiln is composed of the cylindrical shell, the roller supporting device with thrust roller, driving gear unit movable kiln hood, sealing device at kiln inlet, coal dust pipe device etc.

The special features of the kiln system are high productivity, low heat consumption, stable clinker quality and high economic efficiency.

Fuel for this may be gas, oil, pulverized petroleum coke or pulverized coal.

Features of rotary kiln

1. Solid structure, stable performance, high production efficiency.

2. Convenient operation, easy repair. Its energy consumption is reduced by 15% compared with the same kind of products.

3. Rotary kiln is continuous working, without change the existing operating parameters, without consuming any material, the overall economic efficiency improved significantly.

4. The stable performance and advanced structure have greatly improved its preheating effects.

5. In rotary kiln dynamic balance, kiln skin general are uniform smooth rough, material move smoothly, gentle, material layer uniform and stable, and clinker quality are improved.

6. Effectively curb rotary kiln red kiln, rotary kiln knot big and small size egg ball accident, kiln liner and bearing, motor, rotary kiln body can be effectively protected, significantly prolong kiln using life.

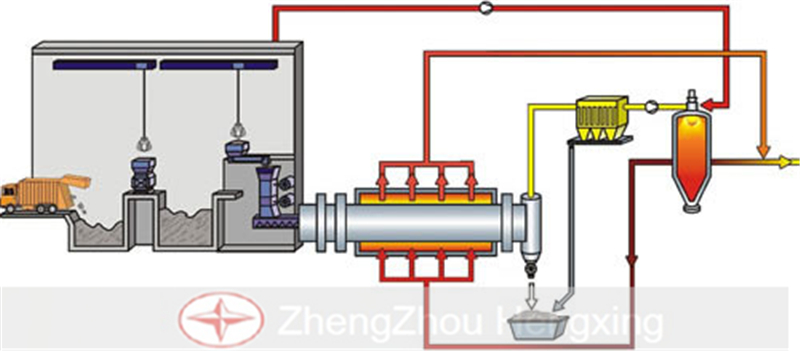

Working principle of rotary kiln

This kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis.

The materials to be burnt get into the stove from the higher end of the cylinder. Due to the slope and slow rotation of the cylinder, the material moves around from top to bottom along the axis to finish its process.

At last, the finished materials get into the cooler through the burner hood. The fuel gets into the kiln through the head of the kiln. The waste gas will be discharged from the end of the kiln after exchanging heat with the materials.

Technical data

|

Specification |

Kiln dimensions |

Motor |

Total |

Note |

||||

|

Diameter |

Length |

Obliquity |

Capacity |

Rotation |

||||

|

Φ2.5×40 |

3.2 |

50 |

4 |

1000 |

0.6-3 |

125 |

278 |

Outside |

|

Φ2.5×50 |

3 |

60 |

3.5 |

300 |

0.3-2 |

100 |

310 |

Alumyte-alumina |

|

Φ2.5×54 |

3 |

48 |

3.5 |

700 |

0.6-3.48 |

100 |

237 |

Outside |

|

Φ2.5×40 |

3.2 |

50 |

4 |

1000 |

0.6-3 |

125 |

278 |

Outside |

|

Φ2.7×42 |

3 |

45 |

3.5 |

500 |

0.5-2.47 |

75 |

210.94 |

------ |

|

Φ2.8×44 |

2.8 |

44 |

3.5 |

400 |

0.437-2.18 |

55 |

201.58 |

Outside |

|

Φ2.8×44 |

2.8 |

44 |

3.5 |

400 |

0.437-2.18 |

55 |

201.58 |

Outside |

|

Φ3.0×45 |

2.7 |

42 |

3.5 |

320 |

0.10-1.52 |

55 |

198.5 |

------ |

|

Φ3.0×48 |

2.5 |

54 |

3.5 |

204 |

0.48-1.45 |

55 |

196.29 |

------ |

|

Φ3.0×45 |

2.7 |

42 |

3.5 |

320 |

0.10-1.52 |

55 |

198.5 |

------ |

|

Φ3.0×60 |

2.5 |

50 |

3 |

200 |

0.62-1.86 |

55 |

187.37 |

------ |

|

Φ3.2×50 |

2.5 |

40 |

3.5 |

180 |

0.44-2.44 |

55 |

149.61 |

Kiln with shaft |

|

Φ3.3×52 |

3.3 |

52 |

3.5 |

1300 |

0.266-2.66 |

125 |

283 |

Kiln with preheater |

|

Φ3.5×54 |

3.5 |

54 |

3.5 |

1500 |

0.55-3.4 |

220 |

363 |

Kiln with preheater |

|

Φ3.6×70 |

3.6 |

70 |

3.5 |

1800 |

0.25-1.25 |

125 |

419 |

Generating |

|

Φ4.0×56 |

4 |

56 |

4 |

2300 |

0.41-4.07 |

315 |

456 |

Kiln with preheater |

|

Φ4.0×60 |

4 |

60 |

3.5 |

2500 |

0.396-3.96 |

315 |

510 |

Kiln with preheater |

|

Φ4.2×60 |

4.2 |

60 |

4 |

2750 |

0.41-4.07 |

375 |

633 |

Kiln with preheater |

|

Φ4.3×60 |

4.3 |

60 |

3.5 |

3200 |

0.396-3.96 |

375 |

583 |

Kiln with preheater |

|

Φ4.5×66 |

4.5 |

66 |

3.5 |

4000 |

0.41-4.1 |

560 |

710.4 |

Kiln with preheater |

|

Φ4.7×74 |

4.7 |

74 |

4 |

4500 |

0.35-4 |

630 |

849 |

Kiln with preheater |

|

Φ4.8×74 |

4.8 |

74 |

4 |

5000 |

0.396-3.96 |

630 |

899 |

Kiln with preheater |

|

Φ5.0×74 |

5 |

74 |

4 |

6000 |

0.35-4 |

710 |

944 |

Kiln with preheater |

|

Φ5.6×87 |

5.6 |

87 |

4 |

8000 |

Max4.23 |

800 |

1265 |

Kiln with preheater |

|

Φ6.0×95 |

6 |

95 |

4 |

10000 |

Max5 |

950×2 |

1659 |

Kiln with preheater |

Previous:

Rotary Lime KilnNext:

Cement MillIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727