+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Ball Mill

Feeding size:≤25mm

Production: 0.5-500t/h

Application: Widely used in dry and wet grinding for all kinds of ores, it also can be used for the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

Processible Materials: Cement, silicate, fertilizer, ferrous metal and non-ferrous metal, glass ceramics, etc.

MOQ :

1

Introduction of ball mill

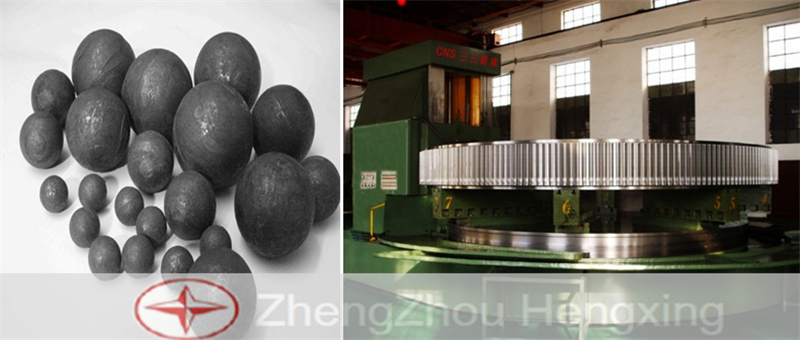

Ball mill is the key equipment for grinding after the crushing process, is an efficient tool for grinding various kinds of materials into fine powder.

It is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics, it also can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Features of ball mill:

1. Large-diameter stick double row self-aligning bearings, replace the plain bearings to reduce friction, reduce energy consumption, the mill is easy to start.

2. Large application range, simple structure and convenient maintenance

3. Inertial impaction equipment running smoothly, and reduce the mill downtime parking maintenance time, improve efficiency.

4. Various barrel lining and grinding media, excellent corrosion resistance.

5. Large-caliber material inlet and outlet, large capacity.

Working principle of ball mill:

A Ball Mill grinds material by rotating a cylinder with steel grinding balls, materials enter the first cabin of ball mills via the feeding device across the hollow shaft uniformly, into the compound empty axis spiral. In the first cabin, which has the ladder liner and corrugated liner with multiple size steel balls, will be lifted to the certain height in the effect of the centrifugal force produced by the rotating cylinder.

Then the balls fall to impact and grind the materials. After the rough grinding process, materials enter the second cabin through the single layer cabin separating board. Steel balls in the second cabin which will grind materials. The finished powder materials are discharged from the unloading plate, thus finishing the grinding process.

Technical data

Model

Speed

Weight

Feeding

Discharge

Yield

Motor

Weight

Φ600x1800

45.5

0.5

≤10

0.075-0.5

0.2-0.5

7.5

2.5

Φ900x1800

38

1.8

≤25

0.075-0.6

0.8-1

15

5.8

Φ900x3000

38

2.7

≤25

0.074-0.3

0.8-1.5

22

7.5

Φ1200x2400

32

4.8

≤20

0.074-0.6

1.5-2

30

9.8

Φ1200x4500

32

5.2

≤25

0.074-0.6

1.5-6

45

15.5

Φ1300x4000

36

5.8

≤20

0.074-0.4

2-6

45

16.7

Φ1500x3500

28.8

8.3

≤25

0.074-0.6

3-5

75

17.6

Φ1500x4500

28.8

10

≤25

0.074-0.4

3-6

110

22

Φ1500x5700

28.8

12

≤25

0.074-0.4

3-8

110

26

Φ1500x6400

28.8

13

≤25

0.074-0.4

3-9

130

29

Φ1830x3600

24.5

12

≤25

0.074-0.4

4-20

130

31

Φ1830x5400

24.5

15

≤25

0.074-0.4

5-25

210

33

Φ1830x6400

24.5

19

≤25

0.074-0.4

6-35

210

36.5

Φ1830x7000

24.5

20

≤25

0.074-0.4

8-40

245

39.6

Φ2100x3600

24.1

21

≤25

0.074-0.6

10-35

210

43

Φ2200x3600

21.8

22

≤25

0.074-0.8

8-35

245

47

Φ2200x7500

21.8

35

≤25

0.074-0.6

10-40

380

68

Φ2200x9000

21.4

36

≤25

0.074-0.6

8-16

475

76

Φ2400x3600

23.36

26

≤25

0.074-0.6

10-40

280

58

Φ2400x7000

22.8

36

≤25

0.074-0.6

10-45

475

79

Φ2400x8000

22.8

42

≤25

0.074-0.6

10-50

560

85

Φ2400x10000

21

65

≤25

0.074-0.6

15-60

710

116

Φ2600x8000

19.6

52

≤25

0.074-0.6

16-20

630

97

Φ2700x3600

21.4

39

≤25

0.074-0.4

13-29

380

86.8

Φ2700x4500

21.4

43

≤25

0.074-0.4

13-26

475

91.88

Φ3000x9000

18.3

78

≤25

0.074-0.6

20-25

1000

152

Φ3200x3600

18.6

56.5

≤25

0.074-0.4

17.5-39.5

630

143

Φ3200x4500

18.6

65

≤25

0.074-0.6

20-30

800

151

Φ3200x9000

18.6

85

≤25

0.074-0.6

25-50

1250

180

Φ3600x4500

18.6

86

≤25

0.074-0.6

30-70

1250

190

(r/min)

with ball(t)

size(mm)

size

(t/h)

power (kw)

(t)

Previous:

Rod MillIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727