+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Mineral Thickener/Mining Thickener

Production: 5.6-560t/h

Application: The concentrator widely used in metallurge, mining, coal, chemicals, building materials, environmental protection and other departments.

Processible Materials: Copper ore, pyrrhotite, hematite, limonite, gold ore, iron ore and so on.

MOQ :

1

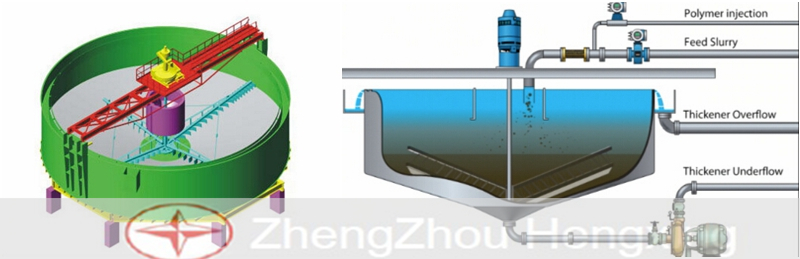

Introduction of Thickener

Thickener is mainly used for concentrating of fine and tailings pulp on ore dressing plants, its structure is simple ,torsion is large, standardization level is high.

It can increase the 20-30% slurry to about 40-70%. The thickener is widely used in metallurgy, chemical industry, coal, non-metallic mineral processing, environmental protection and other industries. It is not the simple settlement equipment, but a new type of dewatering equipment which has mud layer filtration characteristics.

Efficient thickener is widely applied in metallurgy, mines, coal, chemical industry, building materials, environmental protection and other departments, which has significance for improvement of water returning utilization rate and underflow conveying concentration.

Features of Thickener

1. Simple structure, easy operation, maintenance and installation, small footprint, large handing capacity.

2. Setting material receiving plate and cylinder moving down, the feeding evenly and steadily falling, effectively prevent the occurrence of the splashing.

3. Peripheral driven device that drive tray rotating , can control speed stepless , meet the requirements of different production conditions.

4. Unit Processing capacity is improved by 4 ~ 9 times,and energy saving 30%, without any power, low labor costs.

5. Not easy to wear and scrape,long service life.

6. Collector device is fully sealed structure, collecting is reliable and safe.

Working principle of Thickener

Before slurry entering the high efficient concentrator machine, the getter device romoves most of the gas contained in the slurry. Then the slurry feeds into the mixing device through the feed tube, and the slurry thoroughly mixed with an appropriate amout of flocculant in the mixing apparatus to form a good flocculation state.

Then, the slurry flocculation spread around to form a sludge layer in the bottom of the pool. At the same time, the sludge layer plays a role in filtering, preventing fine particles of sludge rise. the not fully flocculated slurry will continue mixing with flocculation and continue growing until reach the slurry layer. Finally, the concentrated material discharged from the central port and the tailing discharged from the overflow port.

Technical data

Central-driven type

Model

Internal(m)

Sedimentation

Rake rotating

Motor

Capacity

Tank weight

Weight

Dia.

Depth

NZS-1

1.8

1.8

2.55

0.5

1.1

1.3-5.6

1.3

NZS-2.5

2.5

1.8

4.9

0.33

1.1

5-10.8

1095

2.4

NZS-3

3.6

1.8

10.2

0.33

1.1

5-22.4

1730

3.0

NZS-6

6

2.95

28

0.3

1.5

14-62

4032

8.7

NZS-8

8

3.318

50.2

0.27

3

11065

17.0

NZS-9

9

3

63.5

0.25

3

32-150

12188

22.7

NZS-12

12

3.6

113

0.19

3

≤250

24060

33.1

area(㎡)

(r/min)

power (kw)

(t/d)

(kg)

(t)

Edge-gear & edge-rubber wheel driven type thickener

Model

Internal(m)

Capacity

Sedimentation

Motor

Weight

Dia.

Depth

NT-15

15

3.5

390

177

5.5

11

NT-18

18

3.5

560

225

5.5

12.1

NT-24

24

3.7

1000

452

7.5

28.3

NT-30

30

3.6

1570

707

7.5

30.9

NT-38

38

4.9

2100

1132

7.5

53

NT-45

45

5.06

2400

1590

11

58.6

NT-50

50

4.524

3000

1964

11

65.5

NT-53

53

5.07

3400

2202

11

69.4

(t/d)

area(㎡)

power (kw)

(t)

Previous:

Disk GranulatorNext:

Agitation Leaching TankIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727