+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Slag Dryer

Production: 1.5-58t/h

Application: Industries of slag, construction materials, metallurgy, ore beneficiation, chemical engineering and cement production.

Processible Materials: Grain slag, blast furnace slag, coal ash, coal cinder, slag, carbide slag, limestone, clay, river sand and silica sand.

MOQ :

1

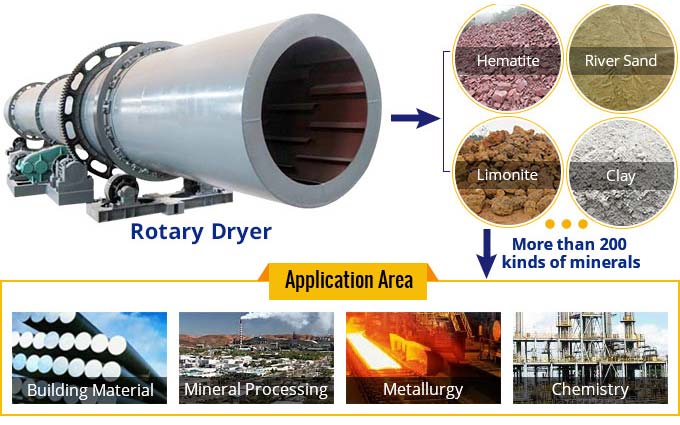

Introduction of slag dryer

Slag dryer is also a kind of rotary dryer, mainly composed of rotary cylinder, induced air equipment, high-speed scattered equipment, feed plate. Slag dryer design is reasonable, well-made, stable performance, advanced technology, high output, low energy consumption, cover a small area, high mechanization degree.

And has the advantages of simple structure, convenient use, is a kind of equipment for the drying machine more affordable. Slag dryer design is reasonable, the production of sophisticated, stable performance, advanced technology, high yield, low energy consumption, small occupied area, a high degree of mechanization.

It is commonly used to dry slag, carbide slag, limestone, clay, river sand, quartz sand and granulating slag in the industries of construction material, metallurgy, ore beneficiation, chemical engineering and cement production.

Features of slag dryer

1. Slag dryer can handle a large quantity and has strong anti- overload capability, high thermal efficiency and low drying cost.

2. In the design in order to achieve the best drying effect, the concurrent flow drying method, material and heat flow into the drying equipment from the same side, the dryer outlet temperature is low, high thermal efficiency;

3. The internal structure of the innovation strengthened the already dispersed material cleaning and heat transfer effect, eliminates the sticking phenomenon the slag dryer flow chart cylinder inner wall;

4. The use of discharging device material, to the model, put an end to the slag drying machine feeding jam, discontinuous, inhomogeneous and material return phenomenon, reducing the dust removing system load for you.

5. Fluorite ore dryer can satisfy the size and moisture requirements of different customers after the drying of slag materials.

6. Instead of traditional cast steel wheel, it can save cost, and reduce maintenance time and money. Simple structure, big capacity, easy maintenance, and it is suited for drying particle.

Working principle of slag dryer

The slag is sent into the hopper by the belt conveyor or bucket elevator and sent into feed end through feeding pipe of feeder hopper. The slag dryer cylinder is a rotating cylinder with a slight incline to the horizontal line.

The materials are sent from the higher end and the heat-carrying agents are sent from the lower end to be countercurrent contact with the materials. Some heat-carrying agents and materials flow altogether into the end of the barrel with the gravity effect as the rotation of the cylinder.

Under the force of oblique blades and hot-air flow, materials inside the dryer move from the feeding end to the star type discharging end and are discharged as final product.

Technical data

Specification

Shell Cubage

Capacity

Installation

Highest

Inlet Air

Main

Weight

Φ1.2×8.0

9.0

1.9-2.4

3-5

700-800

7.5

9

Φ1.2×10

11.3

2.4-3.0

3-5

700-800

7.5

11

Φ1.5×12

21.2

4.5-5.7

3-5

700-800

15

18.5

Φ1.5×14

24.7

5.3-6.6

3-5

700-800

15

19.7

Φ1.5×15

26.5

5.7-7.1

3-5

700-800

15

20.5

Φ1.8×12

30.5

6.5-8.1

3-5

700-800

18.5

21.5

Φ1.8×14

35.6

7.6-9.5

3-5

700-800

18.5

23

Φ2.2×12

45.6

9.7-12.2

3-5

700-800

22

33.5

Φ2.2×14

53.2

11.4-14.2

3-5

700-800

22

36

Φ2.2×16

60.8

13.0-16.2

3-5

700-800

22

38

Φ2.4×14

63.3

13.5-16.9

3-5

700-800

37

45

Φ2.4×18

81.4

17.4-21.7

3-5

700-800

37

49

Φ2.4×20

90.4

19.3-24.1

3-5

700-800

45

54

Φ2.4×22

99.5

21.2-26.5

3-5

700-800

45

58

Φ2.6×24

127.4

27.2-34.0

3-5

700-800

55

73

Φ3.0×20

141.3

30.1-37.7

3-5

700-800

75

85

Φ3.0×25

176.6

37.7-47.1

3-5

700-800

75

95

Φ3.2×25

201

42.9-53.6

3-5

700-800

90

110

Φ3.6×28

285

60.8-76.0

3-5

700-800

160

135

(Dia. x Length) (m)

(m³)

(t/h)

Obliquity(%)

Temperature(℃)

motor(kw)

(t)

Previous:

Raw Material MillNext:

Sludge DryerIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727