+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Sludge Dryer

Production: 0.5-60t/h

Application: The sludge dryer is mainly used by the mining industry to dry materials such as slime, raw coal, peat, flotation clean coal, mixing clean coal and tailings.

Processible Materials: Sludge, raw coal, flotation clean coal, mixing clean coal, slag, clay, bentonite, limestone, sand, quartz stone, metal concentrate.

MOQ :

1

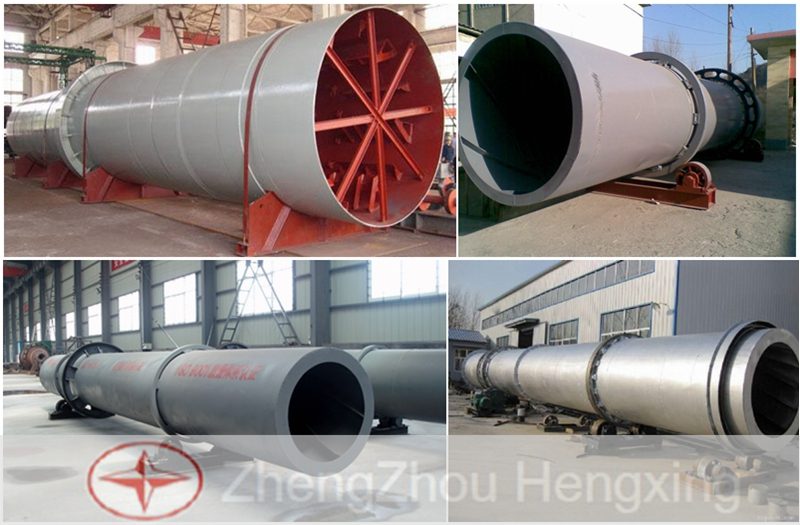

Introduction of sludge dryer

Sludge dryer according to the principle of work belongs to the rotary drum or rotary drum dryer equipment is a kind of very mature mining equipment manufacturer production of drying equipment, suitable for drying coal industry of coal slurry, sludge, magnetic, heavy metal and non-metallic mineral, concentrate and clay cement industry and other industries. It is characterized by high productivity, easy to operate.

Features of sludge dryer

1. Coal slime dryer achieves a “zero thrust” which greatly reduces the wear of roller block, ensuring smooth and reliable operation of the cylinder.

2. Adopt new type multi-combined feeding device, and it can control moisture coal slime drying machinery according to the need of customer.

3. High degree automation and easy operation and stable movement.

4. The investment of equipment is 1/6 of foreign products and income is fast.

5. Adopt tug rotation and low rotating power.

6. Coal slime dryer has a strong anti-overload capability, low fuel consumption, and low drying costs.

7. The fuel is suited for coal, oil, and steam.

Working principle of sludge dryer

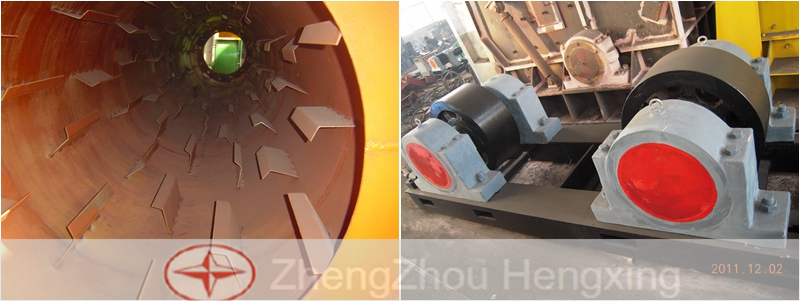

Coal slime is of certain viscosity. In its drying process, the rotary dryer could be divided into the following working areas:

1. Materials lead-in area: in this area, high -temperature hot air contacts wet coal slime, and the moisture in the slime evaporates; under the impact of big-obliquity lifting blades inside the dryer, the coal slime scatters and moves down to next working area.

2. Cleaning-up area: coal slime sticks to the dryer drum when it falls down after being lifted up by the lifting blades; in this area, there is cleaning-up device, which reasonably cleans up the sticky materials from the dryer drum; it also breaks up the lumps or pellets which are already formed by sticky slime; in this way, the cleaning-up device helps enlarge the heat transfer area of the slime and speed up the drying process.

3. Oblique lifting blades area: coal slime in this area is of loose condition with low moisture, and there will be no adhesion phenomena; after being dried by the hot air, the coal slime reaches the ideal condition, and moves to the discharging area.

4. Discharging area: there are no lifting blades in this area; dried coal slime rolls and slides from this area to the discharging mouth to be discharged; the whole drying process thusly comes to an end.

Technical data

Model

Inner

dia.

Shell

Shell

Rotation(r/min)

Power

Dimension

Φ1.0x8

1.0

8

3-6

5.5

8x1.9x2.1

Φ 1.0x10

10

3-6

10x1.9x2.1

Φ1.2x10

1.2

10

3-6

5.5

10x1.9x2.1

Φ1.2x12

12

3-6

7.5

12x1.9x2.0

Φ1.5x12

1.5

12

3-6

15

12x2.6x2.8

Φ1.5x14

14

3-6

14x2.6x2.8

Φ1.8x14

1.8

14

3-6

15

14x3.0x3.0

Φ1.8x18

18

3-6

22

18x3.0x3.0

Φ2.0x18

2.0

18

3-6

22

18x3.2x3.2

Φ2.2x18

2.2

18

3-6

30

18x4.0x3.8

Φ 2.2x20

20

3-6

20x4.0x3.8

Φ 2.4x18

2.4

18

3-6

30

18x4.0x3.8

Φ 2.4x20

20

3-6

37

20x3.6x3.6

Φ 2.8x14

2.8

14

3-6

75

14x4.6x4.6

Φ 2.8x18

18

3-6

18x4.6x4.6

Φ 3.0x20

3.0

20

3-6

110

20x5.0x5.0

Φ 3.2x18

3.2

18

3-6

132

18x8.0x7.0

Φ 3.2x20

20

3-6

20x8.0x7.0

of shell (mm)

length(mm)

(kw)

(m)

Previous:

Slag DryerNext:

Three Drum DryerIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727