+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Mixing Barrel

Power range: 1.5-37kw

Effective volume: 0.58-135.4m³

Internal size of trough/Height: 1000-3000mm

Application: Mixing Barrel mainly used to mix slurry before flotation in the beneficiation process. It is suitable to mix slurry with density smaller than 30 % (weight ratio) and size smaller than 1mm.

MOQ :

1

Introduction of mixing barrel

Mixing barrel is the key equipment by the moving impeller rotation by the motor v-belt drive on behalf of the drugs and pulp fully mixed and increasing the pharmaceutical role reaction time which is useful to strengthen the quality of drug reaction. Mixing vat can be used in ore dressing industry, which also can be applied to some kinds of industrial mixing.

Mineral agitation barrel is suitable for all kinds of metal ore, which is mainly used for mixing before flotation, which is just the full mixing of pharmaceutical and sufficiently slurry can also be the mixing of the other nonmetal material.

The using concentration cannot be greater than 30 %( by weight), and the particle size of the fixed component is less than 1mm. the form of it is the flat-bottomed bucket radiation cycle with the spiral impeller mechanical agitation.

Features of mixing barrel

1. Compact structure, good seal, and feed port settings the block gray board, to prevent the mist playing.

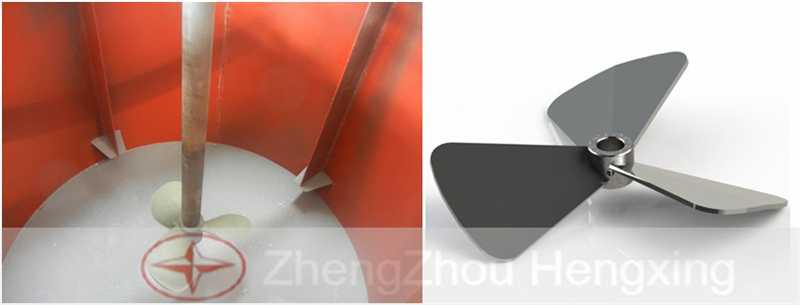

2. It can evenly mix materials because of the fan-shaped mixing blade which can enlarge the contact area of materials and the media.

3. It can evenly mix materials because of the fan-shaped mixing blade which can enlarge the contact area of materials and the media.

4. It is installed with rows of nozzles, and the yield of water is very even and adjustable.

5. The stirring tub has advantages of advanced performance, stable quality of the finished product, even mixing and quick discharge.

Working principle of mixing barrel

When the machine work, by the rotation of the impeller, the pulp and pharmaceutical take circular motion, so that get mixed evenly in the whole tank, and the mixed suspension liquid discharges from the overflow part.

Technical data

Model

Internal

Height

Volume

Impeller

Impeller

Weight

Power

Dimension

XB-500

500

500

0.098

600

200

0.15

1.1

600×566×954

XB-750

750

750

0.26

530

240

0.23

1.5

1131×880×1241

XB-1000

1000

1000

0.58

530

240

0.44

1.5

1131×1130×1492

XB-1200

1200

1200

1.14

320

400

0.76

3

1500×1480×1800

XB-1500

1500

1500

2.2

320

400

1.1

3

1750×1640×2190

XB-2000

2000

2000

5.46

230

550

1.67

5.5

2380×2162×2850

XB-2500

2500

2500

11.2

200

650

3.44

11

3036×2716×3543

XB-3000

3000

3000

19.1

210

700

4.61

18.5

3604×3216×4250

XB-3500

3500

3500

30

230

850

7.11

22

3940×3766×5386

diameter

(mm)

(mm)

(m³)

speed

(r/min)

diameter

(mm)

(t)

(kw)

(mm)

Previous:

Agitation Leaching TankNext:

High Frequency ScreenIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727