+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Spiral Conveyor

Feeding size : 0-5mm

Production: 0-100t/h

Application: Screw conveyor is suitable for continuously conveying loose materials such as powder, granular and small-block materials, such as coal, gravel, sand and lump coal, cement, cereal, and so on. And is not applicable to the transportation of perishable, large viscous , easy-to-caking materials.

Feed material into the rotary dryer or belt conveyor, it can feed powder, small material (example coal, clay etc).

MOQ :

1

Introduction of spiral screw conveyor

Spiral conveyors are an essential part of many conveying and storage systems. They provide a cost-effective, versatile conveying capability due to simple and robust in design.

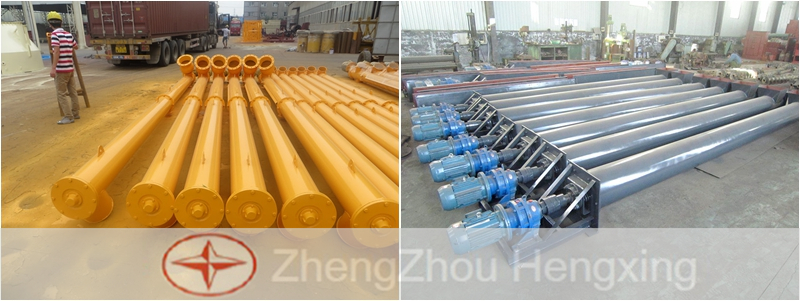

Spiral conveyor (also known as helix conveyors, screw conveyors, spiral conveyors and auger conveyors) is the new generation product that replaced of the GX type screw conveyor. It offers efficiency and versatility, conveying bulk materials ranging from large pellets to sub-micron powders—both free-flowing and non-free-flowing—with no separation of blended products.

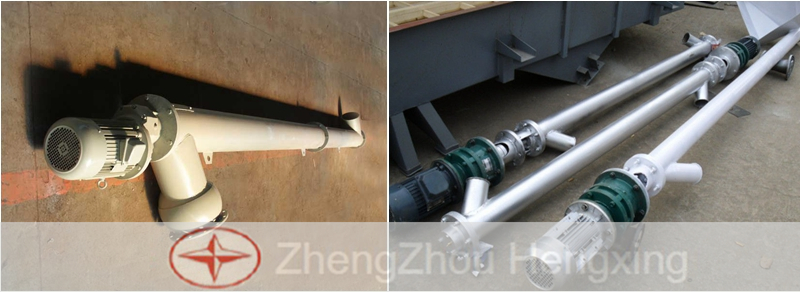

The head and tail bearing have been moved outside from shell. By adopting sliding bearing, dustproof sealed device and slide block, which makes screw conveyor easy to install and maintain. It uses a rotary spiral vane to push materials continuously in closed housing in round section.

Features of spiral screw conveyor

1. Engineered for batch, intermittent and continuous conveying - of free - and non-free-flowing bulk materials.

2. Convey horizontally or vertically – The flexible outer tubing and auger allow for easy maneuvering into elevated hoppers and bending around other equipment and obstacles.

3. Simple, yet rugged construction keeps costs low, reliability high - A helicoid screw rotates inside a fixed tube. Fewer components minimize maintenance.

4. The conveyor’s standard stainless steel construction stands up to a continuous flow of abrasive materials.

5. Easy to clean - Disassemble conveyor in 5 minutes for thorough washdowns.

Working principle of spiral screw conveyor

The material feed into the casing and screw flight was held back by the frication resistance acted on the wall of the casing during running, the screw flight push the material and make the material do axial movement, simultaneity the clockwise and counterclockwise fight act as a mixer.

The material can be discharged at the proper outlet at the bottom of the casing or transport out at the end of the chute. Conveyor with a simple construction, be able to feed and discharge in many position, it is easy to operate, have good seal capability and environmentally friendly.

Technical data

Model

Transporting

Production(t/h)

Power

Weight

Coal

Cement

Raw materials

GX200×10M

3-70

8.5

7.9

7.3

2.2

0.7

GX250×10M

3-70

16.5

15.6

13.8

3

0.95

GX300×10M

3-70

20

21

18.7

3

1.4

GX400×10M

3-70

54

51

45

5.5

2.1

GX500×10M

3-70

79

84.4

74

7.5

3.2

length(m)

(kw)

(t)

Previous:

Aluminum Powder MixerNext:

Steam BoilerIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727