+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Cement Rotary Kiln

Specification: Φ2.5×40m-Φ6.0×95 m

Processing capacity: 180-10000 t/d

Applied material: Dolomite, active lime, cement clinker, and bauxite, non-ferrous and

ferrous metallurgy, iron, aluminum, copper, zinc, tin, nickel, tungsten,

chromium.

Applied area: In addition to calcine cement clinker cement rotary kiln, but also for

calcined clay, limestone and slag drying, refractory materials

production.

MOQ :

1

Introduction of Cement Rotary Kiln

Cement rotary kiln is used for calcination clinker from limestone, clay etc to produce cement. It is the main equipment of the new dry type cement production line.

This equipment is mainly composed of cylinder, supporting device, supporting device with catch wheel, transmission device, lubrication device, mobile kiln head and sealing device at the end of the kiln and it has the advantages of simple structure, reliable operation and easy control of the production process.

The rotary cement kiln belongs to building equipment such as chemical rotary kiln and active lime rotary kiln. According to different materials, there are cement kiln, metallurgy chemical kiln and lime kiln.

Advantages of Cement Rotary Kiln

1. Solid structure, stable performance, high production efficiency.

2. Convenient operation, easy repair. Its energy consumption is reduced by 15% compared with the same kind of products.

3. Stable mechanical performance and transmission, accurate speed control and easy control the calcination temperature.

4. Advanced pre-heating system which accelerates the speed of the kiln and improves the output of unit volume.

5. The sealing effect of this system is perfect and realizes the full utilization of the waste heat.

6. It can roast cement and metal ore with controllable temperature and wide application ranges.

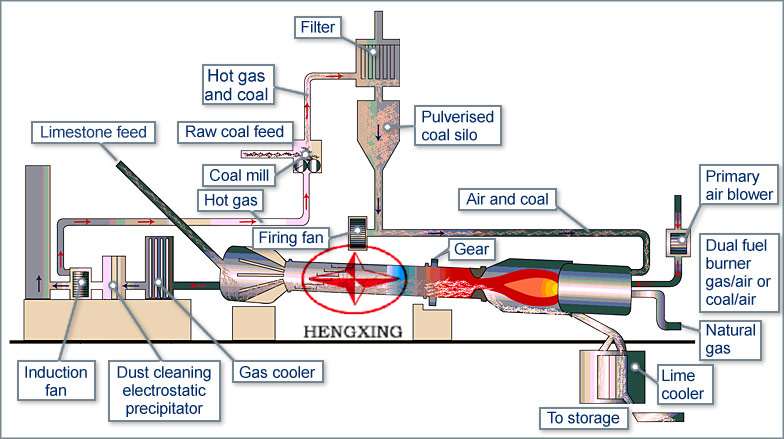

Working principle of Cement Rotary Kiln

Pulverized coal (natural gas) burns inside the rotary kiln and produces heat into stove through gaseous conductance or radiation.

The materials to be burnt get into the stove from the higher end of the cylinder. Due to the slope and slow rotation of the cylinder, the material moves around from top to bottom along the axis.

At last, the finished materials get into the cooler through the burner hood. The fuel gets into the kiln through the head of the kiln. The waste gas will be discharged from the end of the kiln after exchanging heat with the materials.

Technical data

Specifications(m)

Kiln dimensions

Capacity(t/d)

Rotation

speed(r/min)

Motor power(kw)

Total weight(t)

Note

Diameter(m)

Length(m)

Obliquity

(%)

Φ2.5×40

2.5

40

3.5

180

0.44-2.44

55

149.61

Kiln with

shaft cyclone preheater

Φ2.5×50

2.5

50

3

200

0.62-1.86

55

187.37

----

Φ2.5×54

2.5

54

3.5

204

0.48-1.45

55

196.29

----

Φ2.7×42

2.7

42

3.5

320

0.10-1.52

55

198.5

----

Φ2.8×44

2.8

44

3.5

400

0.437-2.18

55

201.58

Outside

disassemble kiln

Φ3.0×45

3

45

3.5

500

0.5-2.47

75

210.94

----

Φ3.0×48

3

48

3.5

700

0.6-3.48

100

237

Outside

disassemble kiln

Φ3.0×60

3

60

3.5

300

0.3-2

100

310

Alumyte-alumina

forge kiln

Φ3.2×50

3.2

50

4

1000

0.6-3

125

278

Outside

disassemble kiln

Φ3.3×52

3.3

52

3.5

1300

0.266-2.66

125

283

Kiln with

preheater precalcine

Φ3.5×54

3.5

54

3.5

1500

0.55-3.4

220

363

Kiln with

preheater precalcine

Φ3.6×70

3.6

70

3.5

1800

0.25-1.25

125

419

Generating

kiln for using ofterheat

Φ4.0×56

4

56

4

2300

0.41-4.07

315

456

Kiln with preheater

precalcine

Φ4.0×60

4

60

3.5

2500

0.396-3.96

315

510

Kiln with

preheater precalcine

Φ4.2×60

4.2

60

4

2750

0.4-3.98

375

633

Kiln with

preheater precalcine

Φ4.3×60

4.3

60

3.5

3200

0.396-3.96

375

583

Kiln with

preheater precalcine

Φ4.5×66

4.5

66

3.5

4000

0.41-4.1

560

710.4

Kiln with

preheater precalcine

Φ4.7×74

4.7

74

4

4500

0.35-4

630

849

Kiln with

preheater precalcine

Φ4.8×74

4.8

74

4

5000

0.396-3.96

630

899

Kiln with

preheater precalcine

Φ5.0×74

5

74

4

6000

0.35-4

710

944

Kiln with

preheater precalcine

Φ5.6×87

5.6

87

4

8000

Max4.23

800

1265

Kiln with

preheater precalcine

Φ6.0×95

6

95

4

10000

Max5

950×2

1659

Kiln with

preheater precalcine

Next:

Rotary Sand DryerIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727