+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Rotary Dryer

Production: 0.5-50 t/h

Main motor power:7.5-160kw

Application: Rotary dryer machine is mainly used in the fields of building materials, mineral processing, metallurgy, chemical industry, etc, it can be used to dry materials with specified moisture.

Processible Materials: limestone, fly ash, coal powder, slag, clay.

MOQ :

1

Introduction of rotary dryer

Rotary dryer machine is divided into many types, for example, limestone dryer, roller dryer, rotary drum dryer and spray dryer.

Rotary drum dryer is strong adaptability to materials and can be used to dry all kinds of materials. This equipment is applied to cement plant for drying limestone, clay, coal powder and mixed materials and also used in metallurgy, mining, electricity, chemical industry and other sectors.

Rotary drum dryer is the most commonly used drying equipment in cement plant. It has many advantages such as sample and reliable operation, excellent dust prevention, good sealing effect and convenient maintenance.

Features of rotary dryer

1. High drying strength, wide applicability, available for many kinds of materials.

2. Short drying time, high processing quantity and high heating efficiency.

3. Simple structure, stable performance, easy to operate and maintain.

4. The rotary dryer can control the temperature of the barrel.

5. Small abrasion wear during movement, long working lifetime.

Working principle of rotary dryer

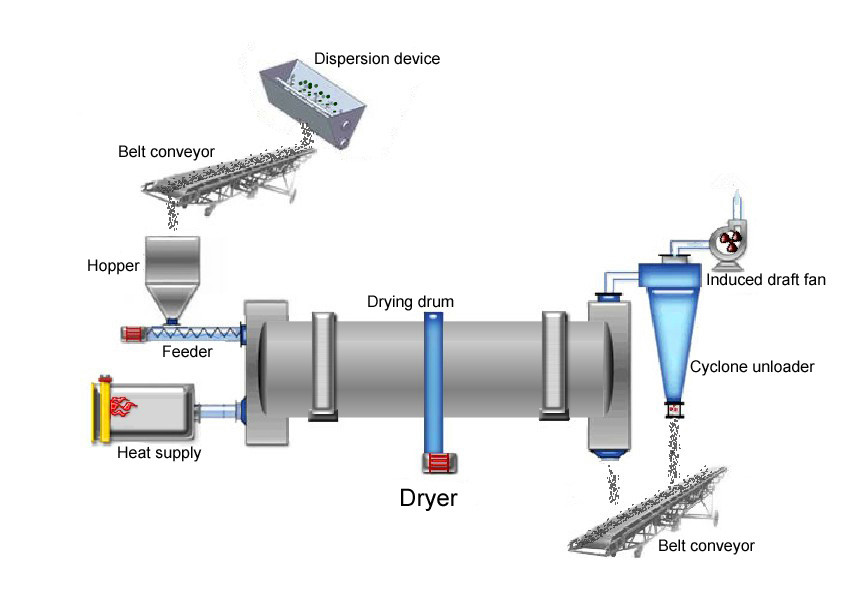

Rotary dryer is made up of the cylinder, lifting plate, transmission, supporting devices and others.

The wet materials are transported into the material hopper by the belt conveyor and bucket elevator and get into the feeding terminal through feeding pipe with the aid of feeder of the material hopper. The pitch of the feeding pipe should be higher than material pitch.

Since the dryer is put slantly, along with the revolving of cylinder, the materials move to the lower terminal due to the gravity. When the wet materials move forward, it receives the heat from the heat carrier directly or indirectly. Heat turns water into steam letting into the air, and aimed dry material is achieved.

Technical data

Specification

Shell Cubage

Capacity

Installation

Highest

Inlet Air

Main

Weight

Φ1.2×8.0

9.0

1.9-2.4

3-5

700-800

7.5

9

Φ1.2×10

11.3

2.4-3.0

3-5

700-800

7.5

11

Φ1.5×12

21.2

4.5-5.7

3-5

700-800

15

18.5

Φ1.5×14

24.7

5.3-6.6

3-5

700-800

15

19.7

Φ1.5×15

26.5

5.7-7.1

3-5

700-800

15

20.5

Φ1.8×12

30.5

6.5-8.1

3-5

700-800

18.5

21.5

Φ1.8×14

35.6

7.6-9.5

3-5

700-800

18.5

23

Φ2.2×12

45.6

9.7-12.2

3-5

700-800

22

33.5

Φ2.2×14

53.2

11.4-14.2

3-5

700-800

22

36

Φ2.2×16

60.8

13.0-16.2

3-5

700-800

22

38

Φ2.4×14

63.3

13.5-16.9

3-5

700-800

37

45

Φ2.4×18

81.4

17.4-21.7

3-5

700-800

37

49

Φ2.4×20

90.4

19.3-24.1

3-5

700-800

45

54

Φ2.4×22

99.5

21.2-26.5

3-5

700-800

45

58

Φ2.6×24

127.4

27.2-34.0

3-5

700-800

55

73

Φ3.0×20

141.3

30.1-37.7

3-5

700-800

75

85

Φ3.0×25

176.6

37.7-47.1

3-5

700-800

75

95

Φ3.2×25

201

42.9-53.6

3-5

700-800

90

110

Φ3.6×28

285

60.8-76.0

3-5

700-800

160

135

(Dia. x Length) (m)

(m³)

(t/h)

Obliquity(%)

Temperature(℃)

motor(kw)

(t)

Shell diameter

Inside

Inside

Shell

Shell

Shell

Lifting

Highest

Dimensions

Φ1.5×15m

1500

500

15

20.27

3-5%

Lifting

form

850

16.2×2.7×2.7

Φ1.5×17m

17

22.97

18.2×2.7×2.7

Φ1.5×19m

19

25.68

20.0×2.9×2.9

Φ1.8×21m

1800

650

21

35.91

3-5%

Lifting

form

850

22.5×2.7×2.7

Φ1.8×23m

23

39.33

24.5×2.9×2.9

Φ1.8×25m

25

42.75

26.5×2.9×2.9

Φ2.2×21m

2200

800

21

58.10

3-5%

Lifting form

850

----

Φ2.2×23m

23

63.61

Φ2.2×25m

×shell Length

diameter

of outer shell

(mm)

diameter

of inner shell

(mm)

Length

(m)

cubage

(m³)

obliquity

blade

form

inlet air

temperature

(℃)

(m)

Previous:

Three Drum DryerIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727