+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Three Drum Dryer

Production: 13-120t/h

Application: Industries of mining, ore beneficiation, construction materials, chemical engineering and metallurgy。

Processible Materials: River sand, coal, iron powder, yellow sand, molding sand, slag and coal cinder, clay, etc.

MOQ :

1

Introduction of Three Drum Dryer

Three-drum dryer also called three-cylinder dryer, is produced by improving the single cylinder dryer.

The three-drum dryer is made up of three layers of sleeves: internal, middle and external one. Both the internal and middle drums are two-dimension ones and the external drum is a vertical one, which makes the most use of the drying drums.

The three-drum dryer is a contact internal heating conduct dewatering unit. During dewatering process, heat is transmitted from the inner wall of the roller to the external wall, passes through the materials on the external wall, and then vaporizes the moisture of the materials. It is a continuous drying machine.

The three-drum dryer's drum length is 25%-35% of the monocular dryer's, thus decreasing the covering area of the machine.

Three-drum dryer or three-cylinder dyer is mainly used to dry granular materials with certain humidity and particle sizes, such as yellow sand, foundry sand, slag, coal cinder, clay with small particle size and other granular materials that resist to high temperature, dust, and smoke.

The moisture content of materials after drying can reach 1 to 0.5 % or below. It is one of the wet materials drying equipment, which is highly efficient and energy-saving product improved on the basis of the single-cylinder rotary dryer.

Three-drum dryer has improved internal structure of monocular dryer, which prolongs the time of pre-drying of wet materials and wet materials in the machine, thus improving 50% to 80% of production capacity compared with the original monocular dryer.

Features of Three Drum Dryer

1. The three-drum rotary dryer is scientific, reasonable, high efficiency and energy saving.

2. The material in the cylinder can exchange with heat flow in the ways of radiation, convection, conduction and other forms.

3. There are a variety of designs of feeding plate which can make the material exchange with hot smoke and gas more fully and reduce the incidence of wind tunnel in the dryer.

4. Three-drum dryer has a compact structure and covers a small area which is half of the single drum dryer does.

5. It can dry 20-40mm of lump material, particle material, powder material.

6. Equipment service life is 3 to 4 times longer than dryer machines which made of common steel plate.

7. Smooth operation, high running rate, less maintenance, low cost, etc.

Working principle of Three Drum Dryer

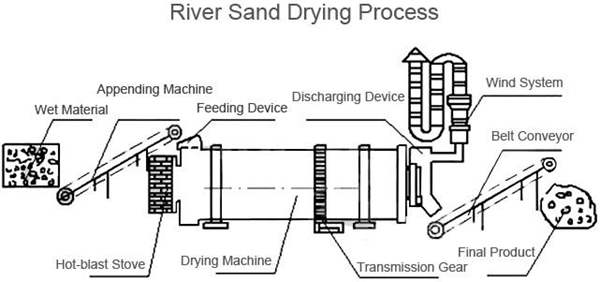

Materials enter the inner side of the drum through the feeding device to realize current flow drying process, then the materials enter the middle layer of the inner wall through the other end to realize counter current drying process.

They are lifted in over and over in the middle layer which advance in two-steps forward and one-step back way. The three-drum dryers absorb heat from both inner drum and middle drum, which extend the drying time and realize the best drying condition.

Finally, materials fall into the external layer of the drum from the other end of the middle layer, processing in a rectangle multi-loop way. The dried materials move quickly out of the drum under the hot air, while the wet ones remain because of their own weight. Materials are dried completely inside the rectangle shoveling plate and then cooled by the single drum cooler, thus finishing the whole drying process.

Technical data

Specification

Cylinder

Cylinder speed

Highest

Inlet Air

Capacity

Motor

Φ2x4.5

14.13

4-10

700-750

13-18

5.5*2

Φ2.2x5

18.99

4-10

700-750

15-23

7.5*2

Φ2.5x6

29.43

4-10

700-750

20-28

5.5*4

Φ2.7x6.5

37.19

4-10

700-750

24-33

7.5*4

Φ3x6.5

45.92

4-10

700-750

35-40

11*4

Φ3.2x7

56.27

4-10

700-750

40-60

15*4

Φ3.6x8

81.39

4-10

700-750

55-75

18.5*4

Φ4.2x8

110.78

4-10

700-750

70-120

22*4

(Dia. x Length) (m)

volume(m³)

(t/h)

Temperature(℃)

(t/h)

power(kw)

Previous:

Sludge DryerNext:

Rotary DryerIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727