+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Cement Mill

Production: 12-200 t/h

Specification: φ1.83×7~φ4.6×14m

Application: Cement mill is widely used in the cement and silicate, new building materials, refractory material, chemical fertilizer, the dressing of black and non-ferrous metal.

Processible Materials: Cement, silicate products, new building materials, refractory materials, chemical fertilizer, etc.

MOQ :

1

Introduction of cement mill

Cement mill is also called cement ball mill, which is mainly used for grinding cement clinker in the cement production process. It is one of the important cement equipment.

Cement mill has the advantages of the small occupied area, stable running, convenient operation and other advantages, so as to achieve the high yield and high fineness, which has provided a strong guarantee for the production of high quality cement. According to the different needs of cement, it can adopt the edge transmission or center transmission, which has a flexible configuration.

Cement miller is widely used for cement, silicate products, new building materials, refractory materials, fertilizer, black and non-ferrous metal and glass ceramics. The cement mill is available in both wet process grinding and dry process grinding.

Features of cement mill

1. High grinding efficiency. The material bed pressure crushing principle is adopted for the rolling, shearing and impacting of materials in the mill. The airflow inside the mill can bring out the ground materials to avoid over-grinding.

2. Large feed granularity. It usually takes up 5% diameter of the grinding roller. Cement mill has superior performance, large output, and high operation rate.

3. Strong adaptability to various materials. It can be used for grinding various raw materials such as limestone, sandstone, coal, cement clinker, hopper, blast furnace slag etc.

4. Excellent overall airtight, less dust, low noise and superior working conditions.

5. The fast quality control and flexible adjustment of products make it easy to realize intelligent and automatic operations.

6. The turning gearwheel of cement mill adopts casting hobbling process and the drum is equipped with wear-resistant liner, which has good wear-resistance.

Working principle of cement mill

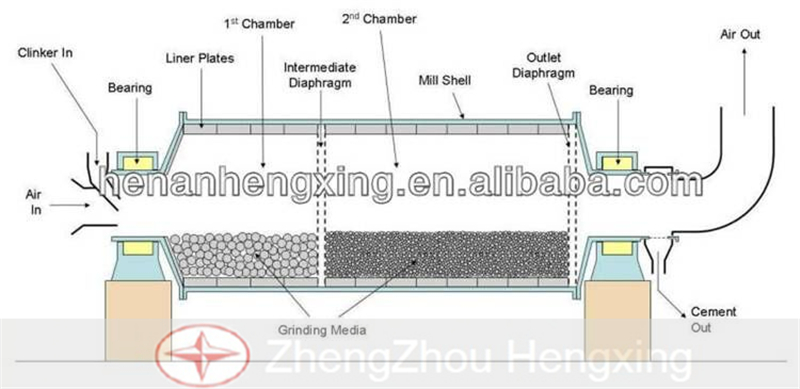

This machine is a horizontal type cylinder rotary device and outside the cylinder, there is drive gear which drives the cylinder to rotate during the working process. Materials spirally and evenly go into the first cabin of the grinding machine through the feeding hollow shaft from the feeding device, and inside the first cabin, there are ladder lining boards or ripple lining board in which there are many steel balls with different specifications.

The cylinder rotates and produces eccentric force to bring the steel balls to a certain height, and then the steel balls will fall down to impact and grind the materials. After being coarsely ground in the first cabin, the materials will go through the single-layer partition board and into the secondary cabin in which there are scale board embedded and steel balls in the warehouse. The materials will be further crushed in this warehouse. The powder will be discharged by the uploading plank. Then, the grinding work will be finished.

Technical data

Model

Cylinder(mm)

Rotating speed

Production

Motor

Weight

Diameter

Length

MX2295

2200

9500

21.4

14-15

475

68.2

MX22110

2200

11000

21.4

15.1-16.1

570

85.6

MX24110

2400

11000

20.68

20.6-22.7

630

108

MX24130

2400

13000

19.4

21.6-23.8

800

121

MX26130

2600

13000

19.7

24.6-27.1

1000

169.8

MX3090

3000

9000

18.7

26.6-28.5

1000

161

MX30110

3000

11000

18.7

28.6-32.8

1250

183.5

MX30130

3000

13000

18.7

33-36

1250

199.5

MX32120

3200

12000

17.8

31.8-38.2

1400

213

(r/min)

capacity (t/h)

power (kw)

(t)

Previous:

Rotary KilnNext:

Raw Material MillIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727