+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

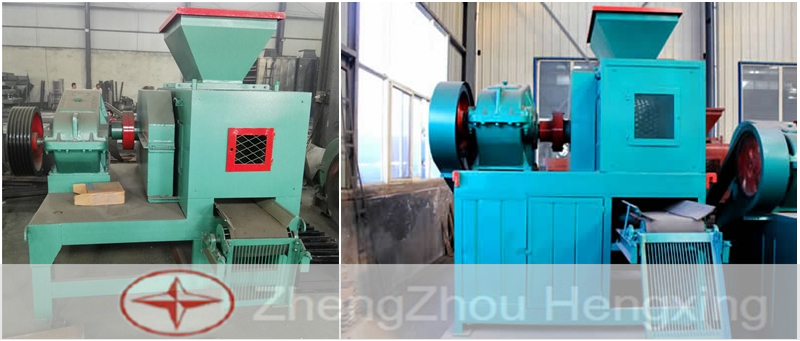

Iron Powder Briquetting Machine

Production: 1-30t/h

Briquetting Ratio: 90-95%

Application: Widely used in refractory, power plant, metallurgy, chemical plant, energy resource, transportation, heat supply, etc.

Processible Materials: Coal powder, iron powder, coking coal, aluminite powder, scrap iron, oxide-scale, carbon powder, charcoal powder, slag, gypsum, tailings, sludge, Kaolin, activated carbon, dust coke and all kinds of powder, powder materials, waste materials, offscum scrap.

MOQ :

1

Introduction of Iron Powder Briquette Machine

Iron ore powder briquette machine (ball press machine, roller press machines) is mainly used for pressing powdery materials with low water content such as all kinds of iron powders, manganese powders, gypsum powders, charcoal powders, ore powder and refractory, coal powder, carbon black powder and other fine powder mineral materials.

Iron powder briquette making machine is forcing roll extrusion so the product has high density, high strength, and high hardness three high characteristics. And the roller is made of 65mm hard materials, with goods wear resistance, improving the lifetime of the roller. The raw material can be directly put into production after crushing without adding water.

Its purpose is to reduce dust, control the bulk density, return to use, and improve transport properties. The finished briquettes can be pillow shape, round shape, ball shape, oval shape, and other shapes. Also, the molds can be customized according to your special requirement.

Features of Iron Powder Briquette Machine

1. Iron powder briquette making machine is low-consumption, energy saving

2. The final briquettes can be designed with different shapes of oval shape, egg shape, pillow shape, square shape etc.

3. The Iron powder ball press machine has strong structure, high briquetting ratio because the briquette machine excellent design

4. It can be the single machine or whole production line.

5. Small size, low power and can move and it is equipped with small conveyor machine.

Structure of Iron Powder Briquette Machine

Feeder system--- achieved dosing feeder to ensure the iron powder feed evenly.

Matching motor--- fine iron powder briquette machine the constant of the electromagnetic motor seed control until the weight of the feeder is equal to the needed weight, then the constant feeder pressure makes the ball with stable quality.

Transmit system--- electromotor-triangle belt-reducer-exposed gear-roller.

Hydraulic protection equipment- iron powder briquette machine has hydraulic protection equipment.

When the iron powder briquette machine is working, the hydraulic pump shot the high-pressure oil into the hydraulic cylinder, cause the piston start an axial movement. The former head of the piston rod against to the bearing housing to meet production pressure requirements.

Technical data

Model

Decelerator

Ratio

Roller size

Shaft

Motor

Capacity

Dimension

HX360-4

ZQ350

1:31.5

Ф360×250

15-17

7.5

3-5

2.26×1.53×1.98

HX360-2

ZQ350

1:31.5

Ф360×250

15-17

7.5

3-5

2.26×1.53×1.76

HX400-4

ZQ400

1:31.5

Ф400×250

15-17

11

4-7

2.3×1.38×1.96

HX400-2

ZQ400

1:31.5

Ф400×250

15-17

7.5

4-7

2.2×1.38×1.91

HX430-4

ZQ400

1:31.5

Ф430×250

15-17

11

5-8

2.4×1.53×2

HX430-2

ZQ400

1:31.5

Ф430×250

15-17

7.5

5-8

2.3×1.53×1.9

HX500-4

ZQ500

1:31.5

Ф500×350

15-17

22

8-10

2.61×1.75×2.35

HX400-2

ZQ500

1:31.5

Ф500×350

15-17

15

8-10

2.61×1.75×2.1

HX650-4

ZQ650

1:31.5

Ф650×350

15-17

30

12-20

3.42×2×2.4

HX650-2

ZQ650

1:31.5

Ф650×350

15-17

22

12-20

3.42×2×2.2

HX750-2

ZQ750

1:31.5

Ф750×380

15-17

30/4

25-30

3.7×2.55×2.6

HX850-2

ZQ850

1:31.5

Ф850×436

15-17

37/4

35-40

3.9×2.6×2.7

HX1000-2

ZQ1000

1:31.5

Ф1000×530

15-17

45/4

40-45

4×2.8×2.8

(mm)

speed(r/min)

power(kw)

(t/h)

(m)

Previous:

Hydraulic Briquetting MachineNext:

Lime Ball Press MachineIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727