+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

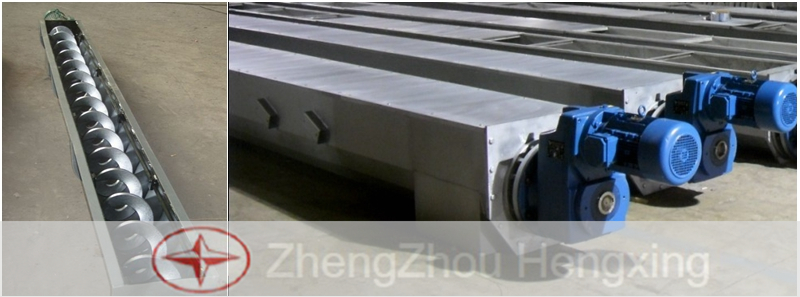

Screw Conveyor

Production: 7~85 t/h

Processible Materials: Cement, lime, raw meal, apatite, urea, fly ash, gypsum etc.

MOQ :

1

Introduction of Screw Conveyor

Screw conveyors are the most widely used type of screw conveyor, which are perfectly suited for transportation of powdery, granular, and wood-based materials. Used to convey bulk materials from one part of a process to another.

Screw conveyors are able to convey materials both horizontally and vertically. Screw conveyors are typically designed to convey bulk materials at 15, 30 or 45-percent trough loading, depending upon material characteristics of the specific bulk material.

As a general rule, trough loading of 45-percent can be used for light, free-flowing and non-abrasive bulk materials. Trough loadings of 15 and 30-percent are typically used for denser, sluggish and more abrasive bulk materials.

Screw conveyors are very cost-effective, highly efficient and durable and require minimal maintenance to operate. Screw Conveyors can be sealed for dust free, corrosion resistance and vapor tight requirements.

Features of Screw Conveyor

1. Self-supporting, completely enclosed, and safe structures

2. It has a compact structure, small cross section, light weight.

3. Highly efficient transportation, flexible technological layout, with easy installation, dismantlement.

4. It is applicable to transport various kinds of soft materials such as powder, granular and small pieces of materials.

5. The screw conveyors are supported by superior quality bearings for smooth and easy operation as well as for low maintenance.

6. Conveying with different angles of inclination.

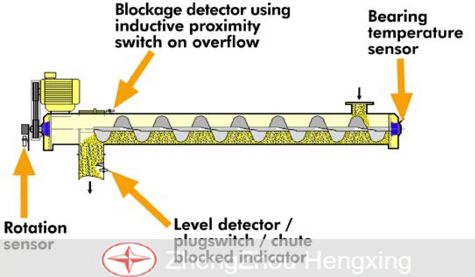

Working principle of Screw Conveyor

Screw conveyor consists of a head bearing, rear bearing, several pieces screw shaft, the outer tube, viewing port. The mobile device is made of the engine, gearbox, and clutch.

The material is introduced through an Inlet chute on top of the conveyor. The materials falls past the screw and build up under the conveyor when the products angle of repose reaches the spiral, the spiral simply moves the material forward and keeps the materials moving forward at the preselected height.

Technical data

Model

Transmission

Production

capacity(t/h)

Power

Weight

Coal

Cement

Raw

material

GX200x10

3-70

8.5

7.9

7.3

2.2

0.7

GX250x10

3-70

16.5

15.6

13.8

3

0.95

GX300x10

3-70

20

21

18.7

3

1.4

GX400x10

3-70

54

51

45

5.5

2.1

GX500x10

3-70

79

84.4

74

7.5

3.2

length(m)

(kw)

(t)

Previous:

Pan Mixer MachineNext:

Disc FeederIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727