+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Spiral Chute

Feeding size: 0.3-2mm

Production capacity: 0.15-12t/h

Application: It is suitable for separating 0.3--0.02 mm size fine minerals as well as other non-ferrous metals, rare metals and non-metallic minerals with proportion differences.

Processible Materials: Iron ore, ilmenite, titanium ore, chrome ore, pyrite, zircon, monazite, rutile, phosphorus ore, tungsten, tin, phosphorus ore, niobium, tantalum ore, etc.

MOQ :

1

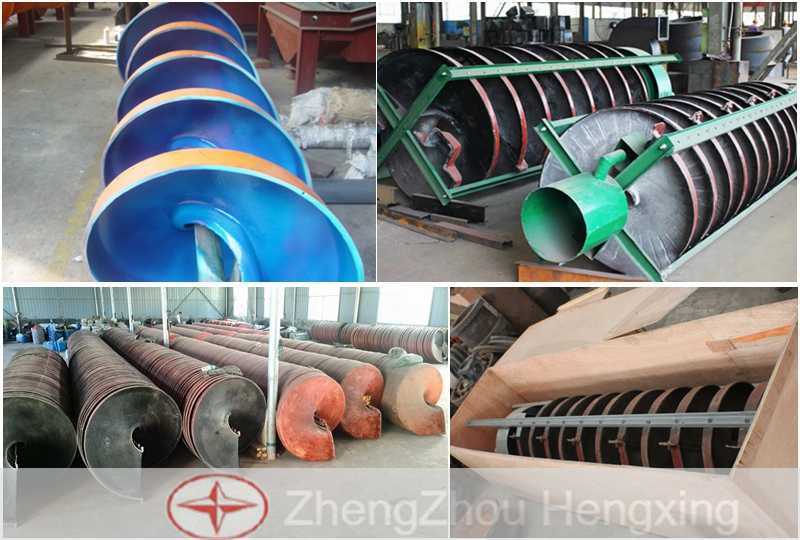

Introduction of gold mining spiral chute

Spiral chute is a gravity separation equipment of separation different weight mineral by inertial centrifugal force pulp produced in helix turning motion. It is the ideal gravity concentration equipment to separate non-ferrous metals, ferrous metals, non-metallic mineral and rare metal mineral. It is also called gravity spiral chute, spiral separator and spiral chute separator.

With the advantages of light in weight, moisture proof, and anti-rust, corrosive proof and no noise; properly suitable for different feeding particle sizes and grades.

Features of gold mining spiral chute

1. Reasonable structure, simple installation and operation, stable, easy control and reliable operation

2. Small cover space, less water consumption, no need of power.

3. Stable ore beneficiation, clear ore separation, high processing capacity and efficiency.

4. Large capacity, enrichment ratio, high recovery rate

5. Light weight, moisture, rust and corrosion resistant, adaptable to fluctuations in ore concentration, particle size, grade, no noise, etc.

Working principle of gold mining spiral chute

Spiral chute is assembled by the screw blade which is made of glass fiber reinforced plastic. The inner surface of the blade is equipped with resistant lining that is made of urethanes or the epoxy resin mixed emery.

Spiral chute is supported on a metal structure shelve. Above it, there are mineral separation machine and receiving shaft, while the products interception machine and the receiving shaft are on the lower part.

Bring ores to the two feeding ports on the head of spiral chute by sand pump. Add water. Adjust the destiny of ore pulp. The ore pulp will fall down because of gravity. A type of centrifugal force will product during this process.

The ore and sand will be divided because of different weights, sizes and granularities by the force of gravity and centrifugal force. Concentrate will flow out though tube. Tailings will flow into the tailings bucket and then be discharged out by a pipe.

Technical data

Model

BL-1500

DL2000

LL-900

LL-600

LL-400

External

diameter

1500

1200

900

600

400

Screw pitch

720, 540

900, 720, 540

645, 540, 405

450, 360, 270

240, 180

Ratio

0.6, 0.45

0.75, 0.6,

0.45

0.75, 0.6,

0.45

0.75, 0.6,

0.45

0.6, 0.45

Transverse

9°

9°

9°

9°

9°

Max. screw

buckets

4

4

4

4

4

Feeding size

0.02- 2

0.3-0.03

0.3-0.03

0.2-0.02

0.2-0.02

Mine density

20-60

25-55

25-55

25-55

25-55

Processing

6-12

4-6

2-3

0.8-1.2

0.15-0.2

Weight

1100

600

400

150

50

Dimension

1600x1600x5800

1360x1360x5230

1060x1060x4000

700x700x2600

460x460x1500

(mm)

(mm)

(screw pitch /dia.)

obliquity(°)

for each machine

(mm)

(%)

capacity (t/h)

(%)

(L x W x H) (mm)

Previous:

Disk Vacuum FilterNext:

Wet Ball MillIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727