+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Wet Ball Mill

Feeding size: ≤25mm

Capacity: 0.65-300t/h

Application: Wet process ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc.

MOQ :

1

Introduction of wet ball mill

Mill is essential and widely used equipment for raw material crushing. Wet ball mill is composed of feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control).

The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance. Bearing adopts oil lubrication system, thus help bearing internal dirt cleaning and reduce the bearing attrition during normal operation.wet ball mill

Advantages of wet ball mill

1. It adopts groove circular plate, which increases connecting area, strengthens the grinding function, and reduces the powe, energy saving should be more than 20%.

2. Wide range of materials processing, high production capacity, unit power consumption is low.

3. Wet ball mill adopts antifriction bearing instead of sliding bearings, which reduces friction and save consumption.

4. Grinding process can be used more sections, forced discharge, velocity faster

5. Large ball mills are equipped with slow transmission device, easily to maintain and start.

6. It adopts the whole frame, convenient for civil construction and device installation.

Working principle of wet ball mill

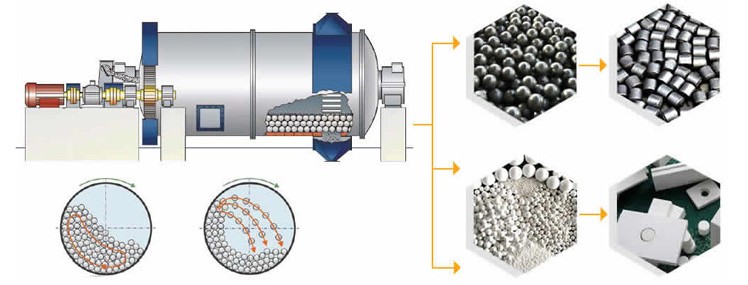

Wet grinding mill is a ball mill with a single bin peripheral discharge device. Materials go into the cylinder body from the feeding end of the hollow shaft. The cylinder body, with a grinding medium (steel ball), is driven by a main motor, a speed reducer and a gear device.

Materials are put in cylinder through the feed opening and then thoroughly grinded, because the falling course of iron balls and ores can produce huge falling impact and autogenous grinding.

The continuous feeding of ores can create considerable pressure to make ores move from feed opening toward discharge opening. Finally, acceptable particles are discharged from the discharge opening. Acceptable ore particles are carried away by water by wet mill, or by air by dry mill.

The discharge opening is equipped with a discharge grate, and the ore pulp horizon of discharge opening is low. These two factors prevent ores from being overly grinded, and iron balls from being dismissed. Under same circumstance, the processing capacity of wet ball mill is bigger. Rolling bearings contribute enormous energy saving.

Technical data

Model

Mr2265

Mr2470

Mr3254

Mr3562

Mr3870

Dia. x Length

φ 2200*6500

φ 2400*7000

φ 3200*5400

φ 3500*6200

φ 3800*7000

Cylinder

volume

21.4

29.3

39.5

55.6

73.6

Max. loading

Material (t)

3.4

5

6

8.7

11.3

Steel ball (t)

24

32

44

64

83

Cylinder

rotating speed

21.95

19.28

16.5

15.47

14.3

Production

18-25

3.-40

45.55

55-70

70-92

Main motor

280

570

630

1000

1250

Reducer ratio

5.0

5.0

4.96

6.74

7.1

Slowly

Motor power (kw)

11

11

11

11

Reduction

ratio

90

500

355

90

Output speed (r/min)

1.62

1.94

2.056

2.06

Dimension (L*W*H)

(mm)

10970*5625*4055

15400*6685*4885

13400*7250*5700

15473*7707*6280

16400*8738*7590

Weight (t)

63

92

122.1

135

180

(mm)

(m³)

capacity

(r/min)

(t/h)

(kw)

drive

device

Previous:

Spiral ChuteNext:

Energy-saving Ball MillIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727