+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

High-Efficiency Fine Impact Crusher

Feeding size: <190mm

Production: 37-315 t / h

Application: Ore crushing, railway, highway, energy, cement, chemical industry, construction, etc.

Processible Materials: Stone with compression strength lower than 350Mpa, such as granite, basalt, limestone, river pebbles, cement clinker, quartz stone, iron ore, bauxite and other minerals, etc.

Brand:

HengxingMOQ :

1

Introduction of High-efficiency Fine Impact Crusher

The PCX high efficient fine impact crusher is the latest generation of high-efficiency fine crusher, this series of impact crushers are designed for crushing ores and rocks with particle size no more than 500mm and compression strength no more than 320MPa.

The high-efficiency fine crusher integrates the advantages of hammer crusher, impact crusher, etc. and is further improved in terms of structure, materials, etc. They enjoy features of high crushing ratio, high-efficient crushing, cubic shape of the product, alternative crushing, etc.

It is used in all kinds of medium hardness solid materials, such as the cement industry, limestone, gypsum, finely clinker, mixed material, etc. It is ideal aggregate processing widely used in expressway, hydro-power construction, airport and building industries.

Features of High-efficiency Fine Impact Crusher:

1. Adopt elasticity constant force and make crushing force stable, with high yield and the product is small in size.

2. Sieve plate adopts special spring concession structure, simple, convenient, reasonable, safe and stable.

3. Adopt high alloy hammer head, it can reduce abrasion, extend lifespan, and has high efficiency.

4. Stable operation, low dust, and less power

5. The distance between discharging grates and rotor can be adjusted. It enjoys steady discharging granularity.

6. The crushing cavity enables the wear-resistant parts to have longer service life.

7. Over-loading protection.

Working principle of High-efficiency Fine Impact Crusher:

When the crusher works, the motor drives the rotor to rotate with high speed, the material into the first crushing chamber crushing and crushing on the plate hammer crushing, and then into the second crushing chamber for crushing.

The materials from large to small all to be crushed at the impact chamber repeatedly. The process won't stop till the material are crushed to the required size and then discharged from the outlet.

Technical data

Model

Feeding port

Feeding

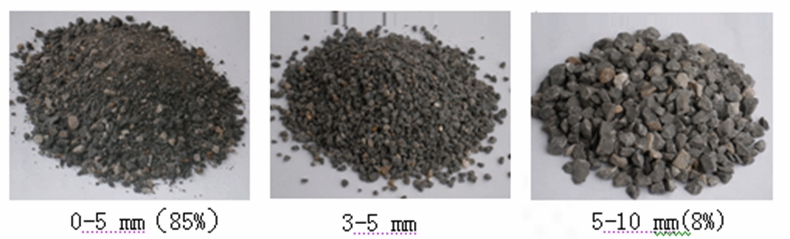

Output size

Discharging

Capacity(t/h)

Power

Cement clinker

Limestone

Glass sand

PXJ800×400

400x185

≤120

≤5

5-20

20-30

35-45

35-45

22-37

PXJ 800×600

500x250

≤180

≤5

5-20

35-40

45-55

45-55

37-45

PXJ 800×800

550x330

≤180

≤5

5-20

35*45

55-65

55-65

37-45

PXJ 1010×1010

1000x350

≤180

≤5

5-20

45-55

65-75

65-75

45-55

PXJ 1200×1000

1200x400

≤180

≤5

5-20

80-110

50-100

50-100

90-110

PXJ 1200×1200

1200x450

≤180

≤5

5-20

100-110

90-100

90-100

110-132

PXJ 1400×1400

1500x500

≤190

≤5

5-20

100-150

100-150

100-150

160

PXJ 1600×1600

1600x550

≤190

≤5

5-20

170-210

190-250

190-250

200

PXJ 1800×1800

1800x800

≤190

≤5

5-20

250-270

280-310

280-310

315

(Rotor*Width)(mm)

size(mm)

size(mm)

(mm)

size(mm)

(kw)

Previous:

Rotary Drum Stone WasherNext:

2-Roller CrusherIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727