+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

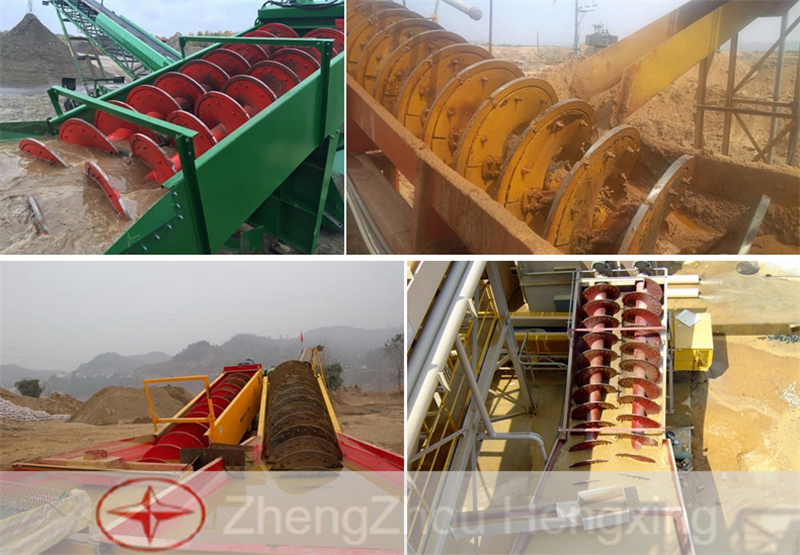

Spiral Sand Washing Machine

Feeding size: 5-40mm

Production: 5-300 t / h

Application: Quarry, minerals, building materials, transportation, chemical industry, water conservation and hydropower, cement mixture station and so on.

Processible Materials: Cement, quartz sand, grit, slag powder, copper ore, iron ore, gold ore, concrete aggregate.

Brand:

HengxingMOQ :

1

Introduction of Spiral sand washing machine

Spiral sand washing machine is mainly used for sand processing, cooperating with sand maker and having functions of cleaning, dewatering and grading, it can remove impurities (such as dust) in sand product.

This spiral sand washing is widely used for ore-sand separation in the ore separation plant. Classify ore sand and fine silt in the gravity separation plant, classify the granularity from the pulp in the metal ore beneficiation flow and remove the slime and water in the ore washing process.

It is designed for washing, medium drainage, classifying and impurity removing operations in metallurgy, building materials, water and electricity industries.

Features of Spiral sand washing machine:

1. Reasonable structure, convenient maintenance, large capacity, small power consumption, clean and high.

2. The novel sealing structure, fully enclosed oil bath type transmission device, the adjustable overflow weir plate, to ensure that the products efficiently.

3. Durable, and cleaning, dehydration, fine-grained product stable characteristics.

4. Saving water resource, without pollution

5. Less material loss after washing, high washing and selecting efficiency.

6. No quick-wear part, long service life.

Working principle of Spiral sand washing machine:

When spiral Sand Washer on an operation , the spiral scatters will rotating , the strength of rotating spiral scatters will push the water going forward. impeller rotating in circles continuously in the water tank and then to make the sandstones and slag particles mixed, inverted and washed in the tank.

The light gravity which is mean the impurities will flow with water , but the clear sand mater will fell down and going forward also by the strength of spiral scatters. Fine ore grains float on the surface of water, and rough grains sink on the bottom of the cell. Finally, the coarse ore particles are pushed by the spiral to the upper part and discharged.

Technical data

Model

Screw

Tank size

Max. feeding

Rotating

Motor

Production

Weight

XSJ-750

750

6000

5-40

18

5.5

5-10

3.2

XSJ-1000

1000

7000

5-40

15

15

8-20

5.2

XSJ-1200

1200

7000

5-40

17

18.5

10-30

6.8

XSJ-1500

1500

7000

5-40

12

22

15-50

9.8

dia.(mm)

(mm)

size (mm)

speed (r/min)

power (kw)

(t/h)

(t)

Previous:

Fine Sand Recovery MachineNext:

Wheel Sand Washing MachineIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727