+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Mobile Crushing Plant

Feeding size: Depending on the process customization

Production: Depending on the process customization.

Application: Sand and gravel field, mining, coal mining, concrete mixing plant, dry mortar, power plant desulfurization, quartz sand, etc.

Processible Materials: Construction waste, basalt, granite, calcite, dolomite, fly ash, cement clinker, river pebbles, limestone, iron ore, bauxite, quartz sand, coal gangue and so on.

MOQ :

1

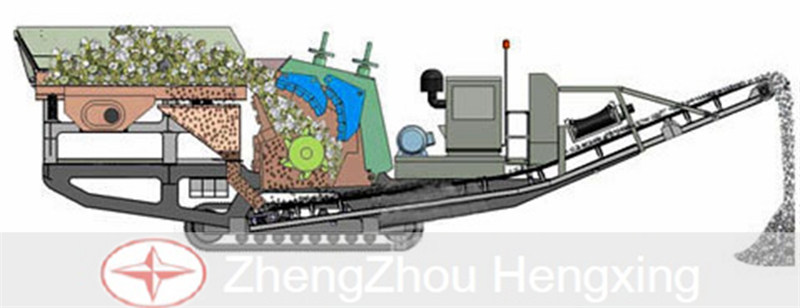

Introduction of Mobile crushing plant

Mobile crushing plant, also named mobile crusher station, portable crushing plant, which uses the latest manufacturing technology, the choice of high quality chrome hammer wear counterattack lining, large ratio of crushing.

It is optimized and innovated in the aspects of structural design, equipment configuration, and combined application, so as to realize more flexible combinations, greatly widen the application fields of wheel mobile crushing plant.

Mobile crushing plant is mainly used in metallurgy, chemical industry, building materials, utilities and other materials processing operations often need to relocate, especially for highways, railways, hydropower projects and other operations stone mobility.

Features of Mobile crushing plant:

1. Flexible configuration, integration of the whole set of units, flexible mobility, reduce material transport costs, operations directly effective, adaptable.

2. High yield, fine particle size, broken product size is less than 10mm or less accounted for more than 80%.

3. Worry-saving for rapidly putting into production, money-saving for flexibility and environmental protection, flexible convenient and versatile. It can save a lot of infrastructure and removal cost.

4. The technology for crushing and screening equipment is mature structure is compact and performance is stable.

5. Wear-resistant parts long life, wear parts long life, maintenance frequency greatly reduced.

6. Safe and easy setup and maintenance thanks to extensive platforms, advanced design, and quick couplings

7. Quick road transportation, pulling the steering shaft to facilitate road transport, with support legs on the truck, site installation fast and convenient.

Working principle of Mobile crushing plant:

Zhengzhou Hengxing equipment production of mobile construction waste disposal station, the use of multi-stage combination model, by the jaw crusher, impact crusher, cone crusher, vibration screening conveyor belt and other combinations. Mobile crushing plant walking with a crawler and tire-type two, according to the regular operation of the road to do different choices.

After the crushing of construction waste, the waste is sorted and removed after crushing, most of them can be reused as renewable resources, such as scrap steel, scrap wire, waste wire and various scrap parts and other metal, sorting, Can be used for the manufacture of artificial wood; brick, stone, concrete and other waste crushed, can be on behalf of the sand, for masonry mortar, plaster mortar, mortar, mortar, mortar, mortar, mortar, , Playing concrete cushion, etc., can also make blocks, paving tiles, tile tiles and other building materials products.

Technical data Mobile crushing plant

Model

YG938F1210

YG938FW1214Ⅱ

YG1142F1214

YG1142F1315

YG1142FW1315Ⅱ

YG1349FW1318Ⅱ

Transportation

11900

11900

13100

13100

13100

14600

Transportation

2550

2550

2800

2900

2800

2800

Transportation

3900

3900

4450

4450

4350

4500

Max. length

12100

12100

13300

13300

13300

14600

Max. width

2900

2950

2950

2950

2950

3250

Max. height

4100

4100

5200

5200

5200

5200

Weight

39

44

44

54

57

62

Impact crusher

PF-1210

PFW-1214Ⅱ

PF-1214

PFW-1315Ⅱ

PFC-1315S

PFW-1318Ⅱ

Max. feeding

300

500

300

350

600

700

Capacity

70-130

130-200

90-180

120-250

180-320

240-400

Vibrating feeder

GZD960×3800

GZD960×3800

GZD1100×4200

GZD1100×4200

GZD1100×4200

GZD1300×4900

Belt conveyor

B800×8.5M

B800×8.5M

B1000×9M

B1000×9M

B1000×9M

B1200×9.5M

Slide-opening belt

B450×3.2M

B450×3.2M

B500×3.5M

B500×3.5M

B500×3.5M

B650×4M

Genset (option)

200

250

250

330

330

380

Iron separator

RCYD(C)-8

RCYD(C)-8

RCYD(C)-10

RCYD(C)-10

RCYD(C)-10

RCYD(C)-12

length(mm)

width(mm)

height(mm)

(mm)

(mm)

(mm)

(t)

size (mm)

(t/h)

conveyor(option)

(option)

|

Model |

Y3S184F210 |

Y3S186F214 |

Y3S216F315 |

Y3S184FW210Ⅲ |

Y3S186FW214Ⅲ |

Y3S216FW315Ⅲ |

|

Transportation length(mm) |

14200 |

16000 |

16000 |

14000 |

16000 |

16000 |

|

Transportation width(mm) |

3100 |

3100 |

3200 |

3100 |

3100 |

3200 |

|

Transportation height(mm) |

4400 |

4400 |

4500 |

4400 |

4400 |

4500 |

|

Max. length mm) |

14600 |

16400 |

16400 |

14400 |

16400 |

16400 |

|

Max. width mm) |

3400 |

3400 |

3500 |

3400 |

3400 |

3500 |

|

Max. height (mm) |

5100 |

5100 |

5500 |

4700 |

4700 |

4700 |

|

Weight (t) |

35 |

41.5 |

47.5 |

34.5 |

41.5 |

48.5 |

|

Impact crusher |

PF-1210 |

PF-1214 |

PF-1315 |

PFW-1210Ⅲ |

PFW-1214Ⅲ |

PFW-1315Ⅲ |

|

Discharging belt conveyor |

B650×7M |

B800×7.5M |

B1000×9M |

B650×7M |

B800×7.5M |

B1000×8.5M |

|

Belt conveyor 1 for re-crushing material |

B650×9M |

B800×10M |

B1000×10M |

B650×9M |

B800×10M |

B1000×10M |

|

Belt conveyor 2 for re-crushing material |

B650×5M |

B800×6M |

B1000×6M |

B650×5M |

B800×6M |

B1000×6M |

|

Under vibrating screen |

B800×6M |

B800×7M |

B1000×7M |

B800×6M |

B800×7M |

B1000×7M |

|

Vibrating screen |

3YZS1848 |

3YZS1860 |

3YZS2160 |

3YZS1848 |

3YZS1860 |

3YZS2160 |

Previous:

Vertical Combination CrusherNext:

Cone CrusherIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727