+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Pulse Jet Bag Filter

Volume: 1710-77700 m³/h

Filtration area: 19-864 ㎡

Application: This kind of bag filter can be used in building material, metallurgy, chemical and refractory industries, especially the crushing, packing, clinker cooling and grinding workshops in cement production. It is also suitable for dust collection of coal grinding after some modification.

MOQ :

1

Introduction of Pulse Jet Bag Filter

Pulse Jet Bag Filter incorporates the advantages of the several kinds of bag filters and is equipped with high performance pulse valve. Bag filters are generally used in application requiring high yield recoveries from pneumatic transport systems, or for the removal of hazardous materials from the working environment.

In an online bag filter, bags are cleaned row by row, even when the dust laden gas is filtered. The sequence of cleaning is controlled automatically by a sequence controller. This operates the assembly of solenoid and pulse valves which direct the air flow into the manifolds. The holes are jig drilled for perfect alignment with the venturi centre for achieving maximum cleaning efficiency.

Such systems may incorporate the use of a cyclone as the primary means of recovery by a bag filter unit for final separation of particles from the air stream. Alternatively the bag filter may be used as the only means of separation.

Advantages of Pulse Jet Bag Filter

1. Automated self-cleaning of filter bags

2. Multi-chamber and off-line dust removing, long life of filter bag.

3. Continuous operation, high filter rates, reduced emissions.

4. High performance pulse is applied to replace many smaller pulse to reduce the maintenance as much as possible.

5. No air pipe. Pulse valve is assembled at the side the chamber shell or top. No need to disassemble and assemble the air pipe when replacing the bags.

6. Unique cleaning system minimizes moisture and particulate issues in pulse valves.

Working principle of Pulse Jet Bag Filter

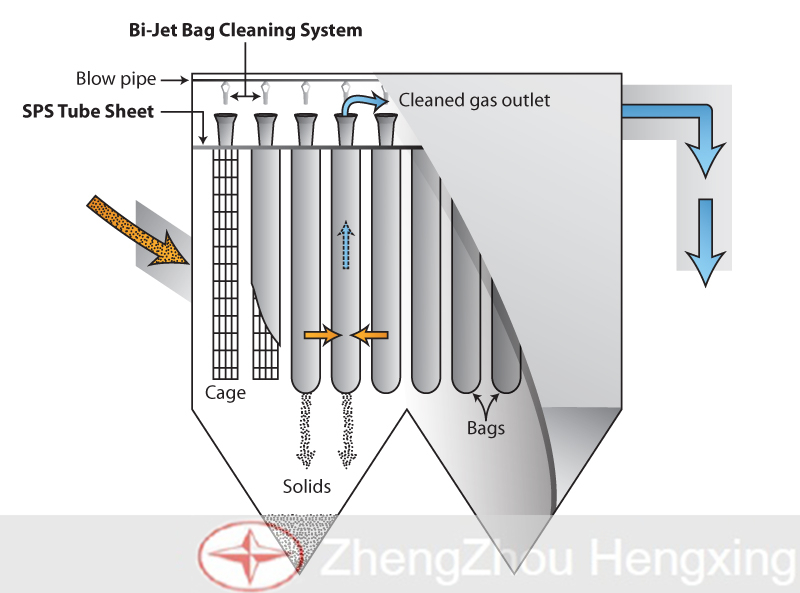

Pulse Jet Bag Filter consists of upper chamber, middle chamber, dust hopper, air inlet and air outlet, as well as support, cage, handrail, air blow system, control system and discharge device.

Dust laden air enters through the hopper by suction (normally on positive pressure). The baffle plate located inside of the inlet act as a pre-filter and the heavier dust particles fall off at the entry itself, while the lighter dust gets carried upward to the bags.

Dust-laden gas is filtered through the bag, depositing dust on the outside surface of the bag. The high pressure compressed air creates a shockwave down each bag causing it to release the majority of dust formed around the outside. This falls into the hopper below.

Clean air passes through the filter bags and leaves the clean air chamber through an outlet duct.

Technical data

Model

Filtration

Filtration

wind

Processing wind

Filtration bag

Efficiency

Air pressure

Dimension

Filtration bag

PHMC24

19

1.5

1710

24

99.9%

0.5-0.7

1200-1500

130*2000

PHMC36

29

1.5

2610

36

99.9%

0.5-0.7

1200-1500

130*2000

PHMC48

39

1.5

3510

48

99.9%

0.5-0.7

1200-1500

130*2000

PHMC60

48

1.5

4320

60

99.9%

0.5-0.7

1200-1500

130*2000

PHMC72

58

1.5

5220

72

99.9%

0.5-0.7

1200-1500

130*2000

PHMC84

68

1.5

6120

84

99.9%

0.5-0.7

1200-1500

130*2000

PHMC96

78

1.5

7020

96

99.9%

0.5-0.7

1200-1500

130*2000

PHMC120

98

1.5

8730

120

99.9%

0.5-0.7

1200-1500

130*2000

PHMC150

122

1.5

10980

150

99.9%

0.5-0.7

1200-1500

130*2000

PHMC180

145

1.5

13200

180

99.9%

0.5-0.7

1200-1500

130*2000

PHMC200

200

1.5

14600

200

99.9%

0.5-0.7

1200-1500

130*2000

PH64-4

256

1.5

23000

256

99.9%

0.5-0.7

1400-1700

130*2500

PH64-5

320

1.5

28800

320

99.9%

0.5-0.7

1400-1700

130*2500

PH64-6

384

1.5

34500

384

99.9%

0.5-0.7

1400-1700

130*2500

PH64-7

448

1.5

40000

448

99.9%

0.5-0.7

1400-1700

130*2500

PH64-8

512

1.5

46000

512

99.9%

0.5-0.7

1400-1700

130*2500

PH96-6

576

1.5

51800

576

99.9%

0.5-0.7

1400-1700

130*2500

PH96-7

672

1.5

60000

672

99.9%

0.5-0.7

1400-1700

130*2500

PH96-8

768

1.5

69000

768

99.9%

0.5-0.7

1400-1700

130*2500

PH96-9

864

1.5

77700

864

99.9%

0.5-0.7

1400-1700

130*2500

area(㎡)

speed(m/min)

amount (m³)

number(pcs)

(Mpa)

(m)

size (mm)

Next:

HydrocycloneIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727