+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Lime Ball Press Machine

Production: 2-50t/h

Roller diameter: 500-1400mm

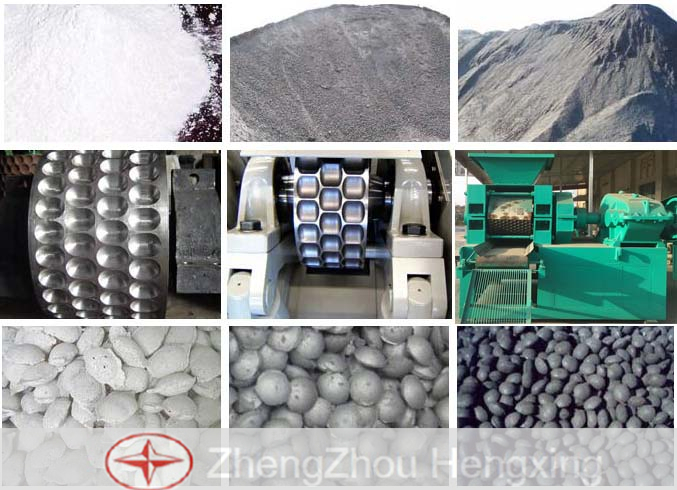

Application: Lime powder briquette machine mainly used in colored and black metal mineral powder briquette making, furnace smelting directly, increase the added value. All the metallurgical industry, waste, ect.

Processible Materials: Dust, mud pool, oxide skin, slag, iron powder, aluminum powder, silicon manganese ore, etc.

MOQ :

1

Introduction of Lime Ball Press Machine

Lime briquette machine can compress lime powder to shape lime briquettes of high intensity, uniform size, and original lime property. The formed lime briquettes are unbreakable during transporting or smelting, and can be used as the auxiliary material of metal smelting.

The lime briquette machinery is widely used in coal, metallurgy and chemical industry and other industries.

Lime Ball Press Machine is mainly used to press powder materials like quicklime powder, dolomite powder, copper concentrate, chromium ore, manganese ore powder, laterite-nickel ore, lead and zinc scrap, bauxite, non-ferrous metal powder, refractory materials, ceramic materials, iron powder materials in steel plant, converter sludge, ferric oxide powder, iron sheet, aluminum skimmings, activated alumina, etc.

Features of Lime Ball Press Machine

1. Simple structure and short technical process.

2. Briquette made by Lime stone powder briquette making machine has higher density, higher calorific value.

3. The surface of the steel plate is painted with four layers of lacquer, making sure the equipment is durable.

4. The Lime powder briquette machine is an easy operation, easy maintenance.

5. Higher bearing ability, longer life-span.

Working principle of Lime Ball Press Machine

Lime powder briquette machine powered by the electromagnetic motor speed. through the belt pulley, cylindrical gear reducer, to the drive shaft by pin coupling. The driving shaft and the driven shaft be ensured synchronous operation through a gear .there is a hydraulic device behind the Passive bearing seat.

Screw feeding drivove by electromagnetic motor speed control. Put the material into feeding port through the belt wheel and the worm reducer. Cause the constant of the electromagnetic motor seed control until the weight of the screw feeder is equal to the needed weight, then the constant feeder pressure makes the ball with stable quality.

But if the feeding quantity is too high will lead to the electrical of the feeder machine overload. And also, it’s not enough to make a ball if the feeding quantity is too small. So Proficiency in operation skills is an important condition to guarantee the normal work of the pressure ball machine.

Technical data

Model

Roll dia.

Roll width

Total pressure

Main motor power(kw)

Output

Weight

GY520-150

520

196

150

55

2.2-3.5

13

GY650-220

650

200

220

110

4-6.5

19.2

GY750-300

750

280

300

185

6-8.5

34

GY1000-350

1000

440

350

250

10-15

50.8

GY1000-450

1000

504

450

280

14-17

58.5

GY1000-500

1000

504

500

315

15-20

58.5

GYS1000-500

1000

600

500

280

17-21

56.5

GY1000-540

1000

900

540

185Kw×2

30-35

60

GY1200-800

1200

900

800

280Kw×2

40

110

GY1400-1000

1400

1000

1000

400Kw×2

50

156

(mm)

(mm)

(t)

(t)

(t)

Previous:

Iron Powder Briquetting MachineNext:

Coal Briquetting MachineIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727