+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Mesh Belt Dryer

Production: 2-20t/h

Application: The Mesh Belt Dryer (Tunnel Dryer) is used to dry the coal/charcoal/minerals briquettes outlet from the briquetting machine. The dryer is applied to complete set of the briquetting production line.

MOQ :

1

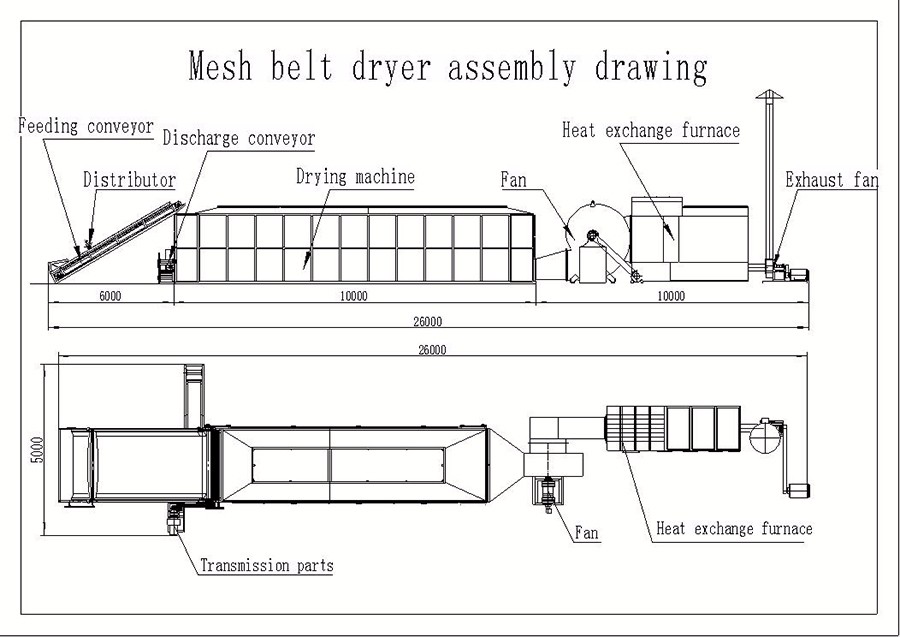

Introduction of Mesh Belt Dryer

The belt dryer is continuous drying equipment in batch. It is suitable for drying the raw materials that are in the shape of the piece, strip or granule and is good in permeability. Particularly it is suitable for such raw materials that contain high moisture and are not permitted high temperature.

Mesh Belt dryer (Tunnel Dryer) uses hot air as the drying medium to contact material continuously, enabling moisture content in the wet material to be gasified and to be evaporated, to achieve the purpose of drying.

It is suitable for drying of charcoal, coal or other kinds of briquette products, also for drying other products with similar size.

Features of Mesh Belt Dryer

1. Materials staying time and feeding speed can be adjusted in order to improve drying quality, the final material drying highly uniform.

2. The equipment configuration is flexible. The mesh belt washing system and materials cooling system are available to use.

3. The material several times with hot air heat and mass exchange, the exhaust air temperature is low, humidity is high, so the device has the characteristics of energy-efficient.

4. The heat source can use steam, thermal oil, electricity, coal (oil), or hot air furnace.

5. The structure of equipment is compact, and the operation and maintenance are simple.

Working principle of Mesh Belt Dryer

The material is distributed to the mesh belt evenly by the feeder. The mesh-belt takes 12-60 mesh stainless steel wire net and it is drawn and moved inside the dryer by a transmission device.

The dryer is composed of several units. For each unit, the hot air is circulated separately. Some exhausted gas is discharged with a special moisture elimination blower.

The waste gas is controlled through an adjusted valve. The hot air passes through the mesh-belt covered with the material from the top to the bottom or from bottom to the top and this will complete the heat and mass transfer process.

This process will bring the material water away. The mesh-belt moves slowly, running speed can be freely adjusted according to the material temperature.

The final products after the drying will fall into the material collector continuously. The top and low circulation units can be freely equipped according to the users’ demand.

Technical data

Model

1001

1503

2203

2205

2208

Single effective

22.5

30.5

36.5

36.5

36.5

Floors

1

3

3

5

8

Effective working

50

105

180

180

108

Accumulation thickness

100-200

100-200

100-200

100-200

100-200

Dry capacity (t/h)

1-2

2-3

8-10

10-15

20-25

Moisture content

8-12

8-12

8-12

8-12

8-12

Moisture content

1.5-3

1.5-3

1.5-3

1.5-3

1.5-3

Transfer power (kw)

2

2

3*3

5.5*5

5.5*4

Air temperature

180-250

180-250

180-250

180-250

180-250

Hot air temperature and

≤0.01kg/kg dry air

working length(m)

width (m)

of materials (mm)

before drying (%)

after drying (%)

requirements(℃)

content requirements

Previous:

Box FeederNext:

Ceramic Sand GranulatorIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727