+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Disk Vacuum Filter

Application: It used for floating and dewatering in clean coal and fine materials like tailings and it can be also used in metallurgy chemical petroleum sewage treatment and other aspects of the solid-liquid separation.

MOQ :

1

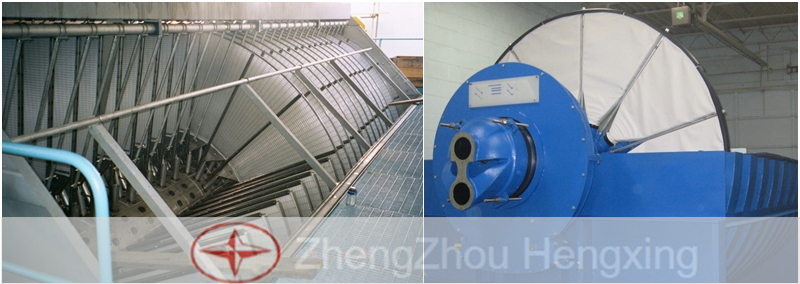

Introduction of Disk Vacuum Filter

Disk Vacuum Filter mainly used for solid-liquid separation with the vaccum as the filtering power. It can be used as the ideal filter for iron concentrate, copper concentrate, sulphur concentrate, Ti concentrate and other non Ferrous Metal concentrate and nonmetal concentrate dewatering and tailing Dewatering.

The split center barrel design with offset flow tubes allows Zhengzhou Hengxing vacuum disc filter systems to increase filtrate removal, reduce wear on each flow tube, and provide a stronger, more efficient snap blow.

Features of Disk Vacuum Filter

1. Highest specific throughput while maintaining a small footprint.

2. Small area taken easy to manufacture and strong adsorption ability, full dehydration.

3. Marked technical and economic effect.

4. Automated operation, high flexibility.

5. Simple maintenance, quick mounting of filter cells and two-part control discs for minimized maintenance effort.

Advantages of Disk Vacuum Filter

1. The capacity of the vacuum filter depends on the filtration speed.

2. If the solids in the suspended liquid are of large and even size, the clearance of filter residue will be less unblocked, and then the filtrate passes faster. Flocculating agent helps gather the fine particles to form lumps, which also increases the filtration speed.

3. For liquid in which solids sediment quickly, the vacuum filter in which add materials from above the filter medium is used to allow the large particles sediment first so as to avoid the block of filter medium and filter residue.

4. If the liquid is hard to filtrate, mix the liquid with large particles such as diatomite or bloating perlite to loose the filter residue; if the liquid is very sticky, heating the liquid helps reduce the stickiness; such doings help increase the filtration speed.

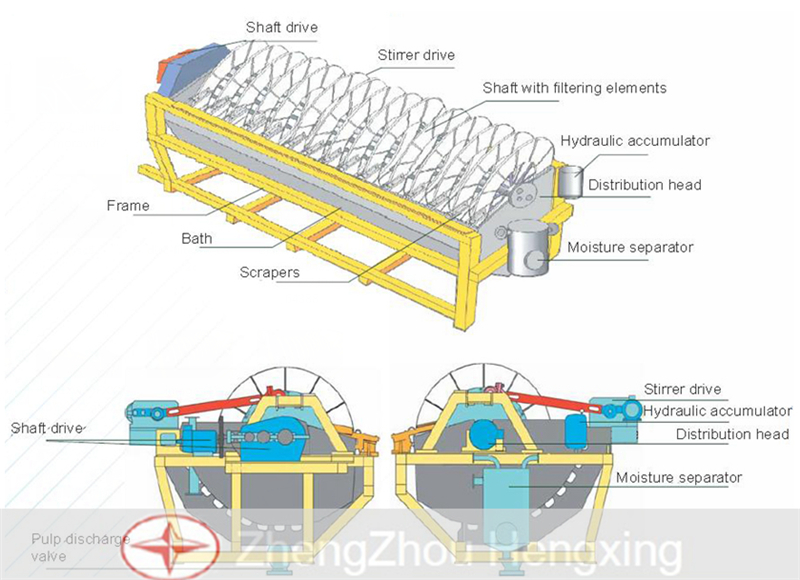

Working principle of Disk Vacuum Filter

A vacuum is produced in the segment-shaped filter cells, which are covered with a filter bag. The liquid filters through the filter cloth, while the solid matter forms a filter cake of uniform thickness on the filter cloth and emerges with the disc from the trough.

As the disc filter rotates, the cake is demoistured by removing the liquid and discharged from the cloth at the end of this zone by means of compressed air (blow-back). The cake is discharged into the chute and further processed.

Technical data

Model

Filtration

Filter disc

Disc RPM

Dia. of disc

Motor

Weight

PG9/2

9

2

0.08-1.89

1800

1.1

3.4

PG18/4

18

4

0.135-1.14

1800

1.1

4.7

PG27/6

27

6

0.135-1.14

1800

1.1

8.4

area

qty(pcs)

(r/min)

(mm)

power(kw)

(t)

Previous:

HydrocycloneNext:

Spiral ChuteIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727