+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

High Frequency Screen

Production: 15–48 t/h

Screen area: 4.5–8.1 m2

Thickness of input material: 30%–40%

Application: Coal, Ore, Limestone, Mining, Metallurgy, Electric Power, Building Materials.

Processible Materials: Iron ore, tin, tungsten, tantalum, niobium, etc.

MOQ :

1

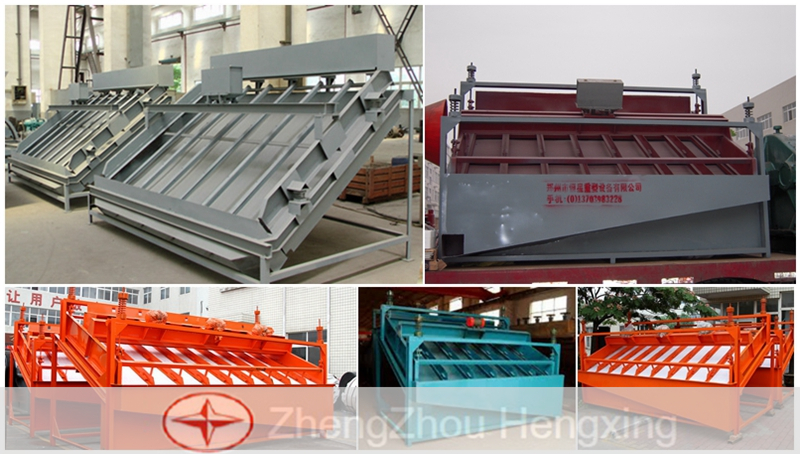

Introduction of high frequency screen

High-frequency screen is also called high frequency vibrating screen, which is a kind of separating equipment in ore dressing plants. It separates materials according to their particle sizes.

High-frequency screen has high efficiency and small amplitude, which is the effective equipment for the screening and grading of fine materials. It is widely used for screening or grading operations in ore dressing plant, such as iron, tin, tungsten, tantalum, niobium sand, etc.

High-frequency screen results in better separation conditions, which make the material which is less than the separation granularity. High-frequency screen is made up with the vibrator, pulp distributor, screen frame, chassis, suspension springs, screens and other components.

Mineral high-frequency screen has the following merits: high efficiency, low amplitude, high frequency screening. The principle of high frequency screen is different from the general screens. High frequency screen adopts the technology of high frequency.

Features of high frequency screen

1. The machine adopts new structural vibrating screening mechanical machine with high efficiency, and which ordinarily takes the screening plate with the material of nylon or stainless steel.

2. Strong exciting force, easy to adjust.

3. Long-term operation and reliable work; screening machine for energy-saving products.

4. Screen box side panel with the overall bending forming steel plate, both to enhance the overall stiffness and reliability of the screening machine.

5. Steel weave mesh, bearing low noise

6. Convenient installation and maintenance.

Working principle of high frequency screen

High efficiency breaks the tension on pulp. So the fine grains vibrate strongly on the surface of the screen, and the heavy useful grains separate out. During that time materials with a size smaller than the screen aperture will be through the screen and materials with a larger size will be discharged from the output, and then finish the final completion of screening.

Technical data

|

Model |

Screen |

Thickness

of |

Capacity |

Power |

|

GPS-4 |

4.5 |

30%-40% |

15-25 |

0.72 |

|

GPS-5 |

5.2 |

30%-40% |

20-30 |

1.1 |

|

GPS-6 |

6 |

30%-40% |

24-36 |

1.5 |

|

GPS-8 |

8.1 |

30%-40% |

32-48 |

2.2 |

Previous:

Mixing BarrelNext:

Rotary ScreenIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727