+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

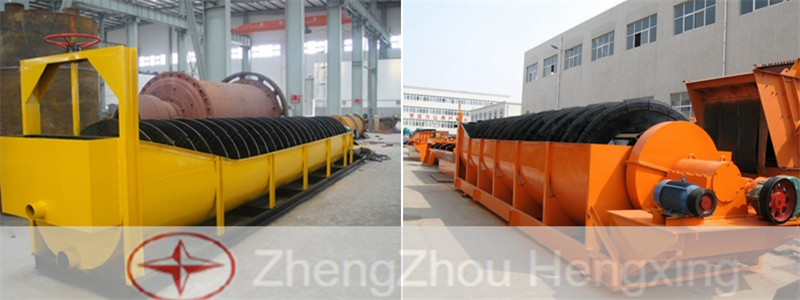

Spiral Classifier

Production: 0.15-6 t/h

Spiral diameter: 300-3000 mm

Application: Cement, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal processing and glass ceramics and other production industries.

Processible Materials: Iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten, tin, tantalum, niobium, pyrrhotite, quartz stone, gold ore, copper ore, etc

MOQ :

1

Introduction of Spiral Classifier

Spiral separator is one mining machine used for ore dressing production, which is also called screw classifier. They can be combined with ball mill to form a closed circuit for preliminary classification and check classification, sometimes they can be applied for ore washing, desliming and dewatering as well

It precipitated in the liquid at different speeds by means of the proportion of solid particles and which is a device of the mechanical grading. The screw classifier can grind the material into the powder level in the filter, and then the coarse material can be discharged from the overflow tube. The spiral classifier is also referred as a grader.

The screw classifiers mainly four types such as high weir single spiral classifier, double spiral, sunken single spiral and double helix classifier.

Features of Spiral Classifier

1. Simple structure and easy to maintain, low power consumption.

2. Easy operation and stable performance, heavy duty, long working life.

3. The powder percentage between 0.00--0.75mm can be adjusted to 2%-15%.

4. The powder quality can be easily controlled, and the granularity adjustment is easy, flexible and credible.

5. A large volume with buffering and conveying effect, better for grinding work.

6. It is easy to operate with variable-frequency control technology.

Working principle of Spiral Classifier

With the help of the drive motor on the top, the whole machine can drive the screw shafts to rotate, all of the spiral blades rotate outwards. The slurry, fed from the flank of the chute, form classification of sedimentation at the bottom of the chute.

Fine ore grains float on the surface of the water, coarse particles dip into the bottom of the chute, and then they will be pushed to the top by the spiral and discharged. During the transportation process, the coarse particles dehydrate themselves.

The fine particles, which do not have enough time to dip into the bottom of the chute, are carried by the ore pulp flow through the surface and discharged from the overflow weir.

There is lifting equipment on the upper beam of the frame, which is used to adjust the distance between the spiral blades and the chute bottom and raise the spiral axle when the machine stops working, in case that the ores deposit and bury the spiral blades to damage the axles and blades when the machine starts working again.

Technical data

|

Type |

Model |

Spiral

Diameter |

Trough |

Spiral rotate (r/min) |

Processing |

Motor Power |

Angle of inclination (%) |

Weight (t) |

||

|

Overflow |

Sand |

Driving |

Lifting |

|||||||

|

High weir single spiral classifier |

FLG-5 |

500 |

4500 |

8.5-15.5 |

22 |

143-261 |

1.1 |

1.5 |

14-18 |

1.6 |

|

FLG-7 |

750 |

5500 |

4.5-9.9 |

65 |

256-564 |

3 |

2.2 |

14-18 |

2.9 |

|

|

FLG-10 |

1000 |

6500 |

3.6-7.6 |

85 |

473-1026 |

5.5 |

3 |

14-18 |

4.4 |

|

|

FLG-12 |

1200 |

6500 |

6 |

155 |

1170-1600 |

5.5 |

4 |

14-18 |

9.4 |

|

|

FLG-15 |

1500 |

8400 |

2.5-6 |

235 |

1140-2740 |

7.5 |

4 |

14-18 |

11.7 |

|

|

FLG-20 |

2000 |

8400 |

3.6-5.5 |

400 |

3890-5940 |

11/15 |

15×2 |

14-18 |

21.5 |

|

|

FLG-24 |

2400 |

10500 |

3-5 |

580 |

6800 |

22 |

22×2 |

14-18 |

33.5 |

|

|

FLG-30 |

3000 |

12500 |

2-4 |

890 |

11650 |

30 |

3×2 |

14-18 |

37 |

|

|

High weir double spiral |

2FLG-12 |

1200 |

6500 |

6 |

310 |

2340-3200 |

5.5×2 |

3×2 |

14-18 |

15.8 |

|

FLG-15 |

1500 |

8400 |

2.5-6 |

470 |

2800-5480 |

7.5×2 |

4×2 |

14-18 |

22.1 |

|

|

FLG-20 |

2000 |

8400 |

3.6-5.5 |

800 |

7780-11880 |

15×2 |

|

14-18 |

36.4 |

|

|

FLG24 |

2400 |

9500 |

3.67 |

1160 |

13600 |

18.5×2 |

2.2 |

14-18 |

48.9 |

|

|

FLG-30 |

3000 |

12500 |

3.2 |

1785 |

23300 |

30×2 |

2.2 |

14-18 |

73.0 |

|

|

Sunken single spiral |

FLC-10 |

1000 |

8400 |

6-7.4 |

75 |

473-1026 |

5.5 |

3 |

14-18 |

6.0 |

|

FLC-12 |

1200 |

8400 |

5-7 |

120 |

1170-1630 |

7.5 |

4 |

14-18 |

11.0 |

|

|

FLC-15 |

1500 |

10500 |

2.5-6 |

185 |

1140-2740 |

7.5 |

4 |

14-18 |

15.3 |

|

|

FLC-20 |

2000 |

11500 |

3.6-5.5 |

320 |

3890-5940 |

11/15 |

1.5×2 |

14-18 |

29.1 |

|

|

FLC-24 |

2400 |

10500 |

3.64 |

455 |

6800 |

22 |

2.2×2 |

14-18 |

35.3 |

|

|

FLC-30 |

3000 |

14300 |

3.2 |

705 |

11650 |

30 |

3×2 |

14-18 |

43.5 |

|

|

Sunken double helix classifier |

2FLC-12 |

1200 |

8400 |

6 |

240 |

1770-2800 |

7.5×2 |

3×2 |

14-18 |

19.6 |

|

2FLC-15 |

1500 |

10500 |

2.5-6 |

370 |

2280-5480 |

11×2 |

4×2 |

14-18 |

27.5 |

|

|

2FLC-20 |

2000 |

12900 |

3.6-5.5 |

800 |

7780-11880 |

15×2 |

|

14-18 |

5.0 |

|

|

2FLC-24 |

2400 |

11130 |

3.67 |

910 |

13700 |

37×2 |

|

14-18.5 |

65.3 |

|

|

2FLC-30 |

3000 |

14300 |

3.2 |

1410 |

23300 |

45×2 |

|

14-18.5 |

84.9 |

|

Previous:

Rotary ScreenNext:

Flotation MachineIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727