+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Magnetic Drum Separator

Shell diameter: 600–1500 mm

Feeding size: 0-3mm

Production: 10-430 t / h

Processible Materials: iron ore, hematite, pyrrhotite, limonite, roasting ore, ilmenite, magnetite, copper ore, gold ore, coal, quartz and so on.

MOQ :

1

Introduction of Magnetic Drum Separator

The magnetic separator, also called magnetic drum separator or magnet separator which is used for removing iron powder is widely applied in resource recovery, the timber industry, mining, ceramic, chemical, food and other workshops, and which is applicable to the granularity below 3mm magnetic wet magnetic separation of iron ore, roasted ore, limonite and other materials, but also for coal, non-metallic minerals, building materials and other materials in addition to ironwork, is the industry's most widely used, general-purpose high one of the models.

The magnetic system of China magnetic separator is always taking of the high-quality ferrite materials or composite with rare earth magnet. The average magnetic induction of the previous drum table of the magnetic drum separator can be 8000-4000mt. The magnet separator can be made of roll-shaped due to the development of the technology and the magnetic strength of the magnet separator can also be improved to 8000mt, which has been the highest magnetic field strength all over the world.

Features of Magnetic Drum Separator

1. Good separation effect: This machine adopts the dynamic magnetic system. The raw ores slide, move and roll on the surface of the drum, and there are no ores sticking to the drum, which helps separate different ores. The grade can be improved 1-4 times in the first separation process, and the grade can reach 60% in a fine separation process.

2. Large capacity: By using wrapped type open magnetic system, the materials do not stick together and the blocking phenomenon can be avoided, which leads to large capacity. The feeding capacity of an individual magnetic separator is at least 50 tons. And the machines can be connected together to be put into use so as to improve the capacity.

3. Wide application: This type magnetic separator can be divided into 4 categories, more than 20 types and models, which can meet the needs of iron ore, river sand, tailings, slags, steel ash, sulfate slag, grinding materials, refractory, plating, rubber, food industries and etc. Some of them are with multi-purposes.

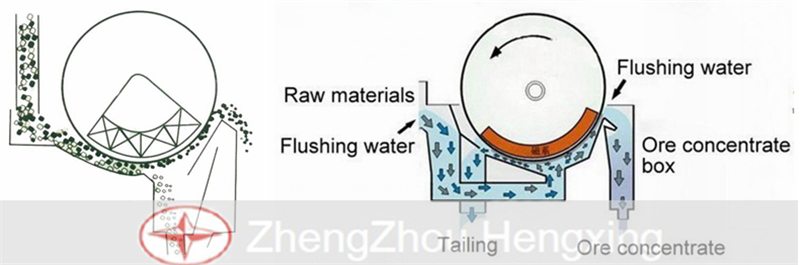

Working principle of Magnetic Drum Separator

The slurry enters chute through ore tank, and then gets into separating zone by waterpower. Magnetic particles form into magnetic ball or linkage with the force of magnetic field. The magnetic ball and linkage are absorbed on the drum during they are moving towards magnetic pole with the magnetic force.

When the magnetic ball and linkage are rotating with the moving drum, because of alternating polarity and magnetic stirring, the gangue and other non-magnetic ore mixed in magnetic ball and linkage are fall down, while magnetic ball and linkage are absorbed on the surface of the drum. These are concentrates we need.

The concentrates come to the field where the magnetic is the weakest with the rotating drum. Then they fall in to concentrate slot by the water flow. But the full magnetic roller uses brush roll to discharge ores. At last, the non-magnetic or weak magnetic minerals are discharged out of the cell with plump.

Technical data

Model

Shell

diameter(mm)

Shell length

(mm)

Shell

rotation speed(r/min)

Feeding size

(mm)

Processing

capacity(t/h)

Power

(kw)

CTB6012

600

1200

<35

2-0

10-20

1.5

CTB6018

600

1800

<35

2-0

15-30

2.2

CTB7518

750

1800

<35

2-0

20-45

2.2

CTB9018

900

1800

<35

3-0

40-60

3

CTB9021

900

2100

<35

3-0

45-60

3

CTB9024

900

2400

<28

3-0

45-70

4

CTB1018

1050

1800

<20

3-0

50-75

5.5

CTB1021

1050

2100

<20

3-0

50-100

5.5

CTB1024

1050

2400

<20

3-0

60-120

5.5

CTB1218

1200

1800

<18

3-0

80-140

5.5

CTB1224

1200

2400

<18

3-0

85-180

7.5

CTB1230

1200

3000

<18

3-0

100-180

7.5

CTB1530

1500

3000

<14

3-0

170-280

11

Previous:

Manganese Magnetic SeparatorNext:

Ceramic Ball MillIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727