+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

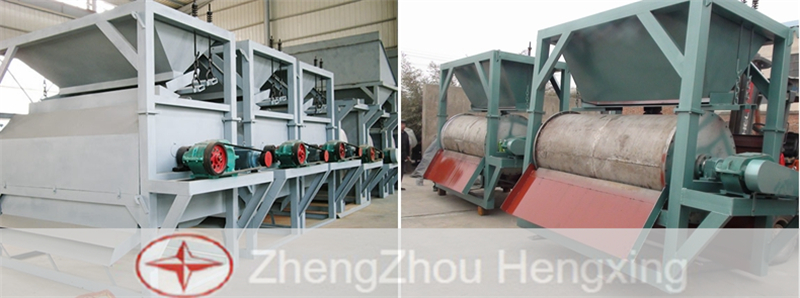

Manganese Magnetic Separator

Feeding size: 0-5mm

Production: 2-30 t / h

Application: Size below 5mm, weak magnetic minerals such as hematite, limonite, manganese carbonate, manganese oxide, tungsten, tantalum and niobium ore etc.

Processible Materials: Manganese ore, hematite, pyrrhotite, limonite, roasting ore, magnetite, and so on.

MOQ :

1

Introduction of magnetic separation

Magnetic separation machine for poor manganese ore, manganese ore per tonne magnetic separation processing consumes only about 0.2 degrees, to a one-time particle size less than 15 mm of poor manganese ore enrichment and improve manganese grade 3~18 degrees, greatly solve the difficult problem of poor separation of furnace smelting manganese ore. Magnetic separation for rare earth minerals, recycling, can disc separator, the shaker is not recovered sufficiently dilute tailings recycling, utilization and recovery of up to 95%: for the zircon, rutile, niobium, tantalum magnetic ore separator can achieve a one-time purposes.

Manganese ore separator has high magnetic field intensity, gradient, with low power consumption, stable performance, wide applicability etc. Hengxing manganese magnetic separator for poor manganese ore by magnetic separation, can one-time particle size of less than 5 mm of lean manganese ore enrichment, improve the manganese grade 5-18%, very good solution over the years can not be put into the smelting furnace manganese ore, a big problem difficult to solve.

Features of magnetic separation

1. Energy saving, consumption of a small amount of electricity only in equipment operation process can, no consumption of exciting current.

2. Magnetic system using open design, material non-clogging phenomenon. A magnetic system by direct contact with material drum protection, easy to protect magnet.

3. Magnetic system of magnetic material on the surface of the cylinder to generate swing sliding displacement and tumbling, clean the effect on the drum, the drumstick material, and is conducive to the separation of the loose and magnetic materials.

4. It adopts vertical ring rotation and recoil concentration. Washing concentrate direction is opposite to ore feeding direction, coarse particles can be flushed without going through the magnetic medium stack, thus effectively preventing blockage of magnetic media.

5. Set slurry pulsation mechanism, driving the slurry generates pulsating fluid force. Under the action of pulsating fluid force, the ore grains in the slurry are always in a loose state, which can improve the quality of magnetic concentration.

Working principle of magnetic separation

Magnetic roller through the speed regulating motor, speed adjusted by speed table, can control the output of magnetic separator, and concentrate grade. Particles by magnetic roller conveyor belt was sent to the sorting, in under the action of electromagnetic vibration feeder, when the selected material evenly through the magnetic field, the magnetic particles and the non magnetic particles in the magnetic force of magnetic particles of different, will be affected by the magnetic force in the sector magnetic field.

Because of the manganese ore grain of magnetic adsorption was immediately magnetic field on the magnetic roller, the gangue minerals with no magnetic, magnetic roller strong magnetic suction on it does not, as the rotation of the magnetic roller manganese grain has been on the magnetic roller, absorption and gangue particles in magnetic roller to the front position thrown off in front of the ore plate isolation (ore by changing plate angle can be adjusted the size of the concentrate grade), manganese ore particles continue to be magnetic roller to magnetic area automatically fall off into a collection bucket collection to concentrate the finished product.

Because of the magnetic roll of the gangue also entrainment some magnetic weaker manganese ore grain, they will enter the magnetic roller continue magnetic separation, magnetic separation of finished product manganese grain into two anthologies ore dou collection for the finished product, was thrown by the gangue by tailings discharge, thus magnetic separation process is over.

Technical data

|

Model |

Magnetic field intensity(Gs) |

Feeding size (mm) |

Processing capacity(t/h) |

Power (kw) |

|

QCG-2-60-110 |

12000-14500 |

0.4-5 |

2-3 |

1.1 |

|

QCG-2-110-150 |

12000-14500 |

0.4-5 |

4-5 |

1.5 |

|

QCG-2-150-220 |

12000-14500 |

0.4-5 |

4-6 |

1.5 |

|

QCG-2-220-320 |

12000-14500 |

0.4-5 |

5-7 |

3.0 |

|

Model |

Magnetic field intensity(Gs) |

Processing capacity(t/h) |

Power (kw) |

|

|

CTB1018 |

1800 |

3-8 |

5.5 |

|

Previous:

Flotation MachineNext:

Magnetic Drum SeparatorIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727