+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

Cyclones Dust Collector

Application: Metallurgy, casting, building materials, chemical food, cement and other industries.

MOQ :

1

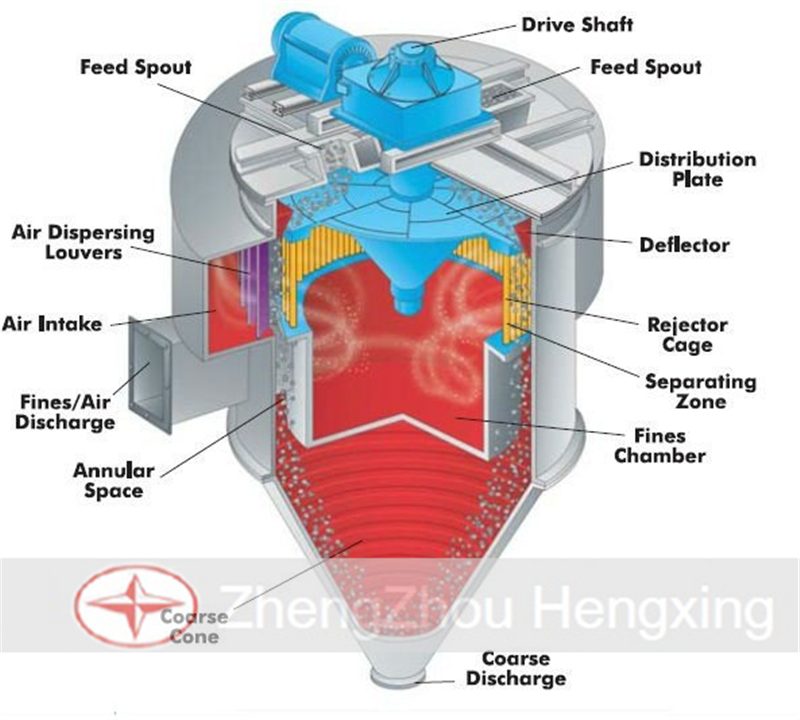

Introduction of cyclone dust collector

Cyclone dust collector is designed specifically for high dust load, high temperature, and product recovery applications. It has a mechanical separator that uses centrifugal force to remove large and high-volume dust from industrial applications.

Cyclone dust collector is designed specifically for high dust load, high temperature, and product recovery applications. It has a mechanical separator that uses centrifugal force to remove large and high-volume dust from industrial applications.

It is a high-efficiency cyclone separator designed to effectively remove large to moderate size particles (chips, metal grindings, sawdust) from the air stream. Used alone or in conjunction with another dust collector, the Cyclone separates coarse contaminants from fine, non-visible particles and exhausts clean air.

Features of cyclone dust collector

1. simple structure, no moving parts, do not need special accessory equipment, cover small areas, less investment in manufacturing, installation.

2. Low running cost, optimized parameter design, stable operation, low resistance and high efficiency.

3. Reliable performance, guarantee the stable operation of duster accompany with the crushing equipment, less maintenance.

4. Removable cone section for easy replacement, wide adaptability, be suitable for a wide range of dusty gas.

5. The airtight sealing system ensures minimum dust leakage.

Working principle of cyclone dust collector

Dirty air enters the unit at a high speed and is then spun around in a spiral motion, throwing particles against its cone wall. Centrifugal force pushes the larger or heavy dust particles down through the narrow part of the cone and into a collection drum or hopper.

The dust once in contact with the wall, will lose the inertia force and momentum near the entrance velocity and its own gravity along the wall falling into the collection bucket. Rotary airflow decline at the cone base, axial position along the precipitator to up. The formation of internal rotation flow increased, and the exhausting from collector tube.

Cleaned air runs back up through the center of the unit and is discharged back into the atmosphere or into an after-filter for further processing.

Technical data

Model

Inlet

wind

Wind

volume

Resistance

Efficiency

Dimension

Weight

CLK-Ф150

10-20

210-420

100

95

380×1210

33

CLK-Ф200

10-20

370-735

100

95

466×1916

52

CLK-Ф250

10-20

595-1190

100

95

566×2039

75

CLK-Ф300

10-20

840-1680

100

95

631×2447

103

CLK-Ф3150

10-20

1130-2270

100

95

716×2866

143

CLK-Ф400

10-20

1500-3000

100

95

808×3277

225

CLK-Ф450

10-20

1900-3800

100

95

893×3695

279

CLK-Ф500

10-20

2320-4650

100

95

983×4106

347

CLK-Ф600

10-20

3370-6750

100

95

1150×4934

612

CLK-Ф700

10-20

4600-9200

100

95

1325×5176

819

speed(m/s)

(m2/h)

(Pa)

(%)

(mm)

(kg)

Previous:

Shake TableNext:

Super Fine Rotor Powder ConcentratorIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727