+86-137-8347-1727

+86-137-8347-1727

Products List

Related Product

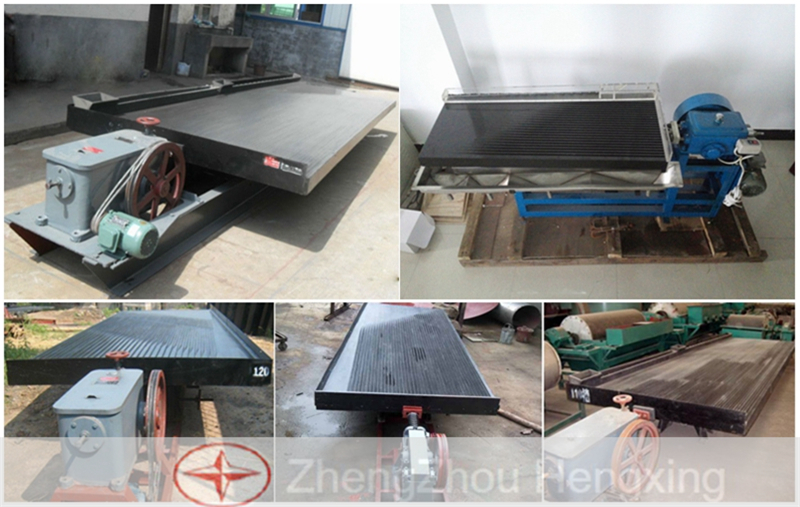

Shake Table

Production: 10–60 t/h

Feeding size: 0.15–2 mm

Feeding thickness: 15–30%

Application: Shaking table which is one gravity separation machine can be widely applied in separating minerals, especially for separating gold and coal.

Processible Materials: Tin ore, tungsten, gold and silver ores, lead, zinc, tantalum, niobium ore, iron, manganese, titanium, and coal, etc.

MOQ :

1

Introduction of Shake Table

Mineral processing shaking table is usually composed of three parts: the bed, rack and transmission mechanism; besides the above, there are also flushing tank, feed chute, and base.

Shaking table is one kind of main equipment of gravity concentration, which is widely used in minerals separation of tungsten, tin, tantalum, niobium, gold and other rare metals and precious metal ores.

It is applied in different separations of rough concentration, elaborate concentration and scavenging concentration, which can process coarse sand (2-0.5mm), fine sand (0.5-0.074mm) and ore slurry(0.074). It also can be used in processing iron, manganese ore and coal. The effective recycling granularity range of shaking table is 2-0.22 millimeters during processing tungsten, tin ores.

Features of Shake Table

1. High concentration ratio, high concentration efficiency, easily operated, and once gets the final concentrate and gangue.

2. Easiness to take charge and easy to adjust, simple to tune for optimal performance.

3. Keep table surface operate balanced even though changing cross fall and stroke.

4. The springs with compact structure are placed on the table.

5. The final concentrated ore and gangue can be obtained once.

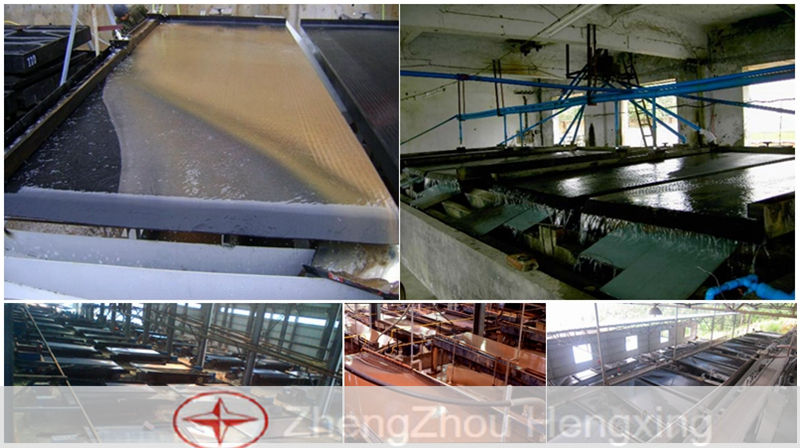

Working principle of Shake Table

Shaking table consists of head motion, decks, and frame, feed, and water box. The beneficiation process is worked on the tilting deck with grooves.

Feed the material into ore feeding port and water into water feeding port. It affected by impulsive force of the horizontal water flow, inertia force and frictional force caused by the asymmetric reciprocating movement of the deck.

Then the mineral particles are separated based on their different specific gravity and particle size to form a fan-shape. Finally, the material are separated and discharged as concentrates, middlings and tailings.

Technical data

Model and Specification

Grit concentrator

Fine sand

Sludge concentrator

Table Size(mm)

Length

4450

4450

4450

Driving part Width

1855

1855

1855

Concentrate part Width

1546

1546

1546

Feeding

size (mm)

2

0.5

0.15

Feeding

capacity (t/d)

30-60

10-20

15-25

Density

(%)

25-30

20-25

15-25

Stroke

(mm)

16-22

11-16

8-16

Frequency

(F)

45-48

48-53

50-57

Bed surface Water quantity

(t/d)

80-150

30-60

10-17

Bed surface Horizontal obliquity(°)

2.5-4.5

1.5-3.5

1-2

Bed surface Portrait obliquity

(%)

1.4

0.92

----

Table board corner(°)

32-42

40

42

Concentrating area(㎡)

7.6

7.6

7.6

Bed surface Length ratio

2.6

2.6

2.6

Shape of side-bed surface

Rectangle

Zigzag

Triangle

Motor power(kw)

1.1

1.1

1.1

table

concentrator table

table

Previous:

Coal MillNext:

Cyclones Dust CollectorIf you need more details about our products, please write what you need, we will contact you asap with favorable prices!

+86-371-67858720

+86-371-67858720 +86-371-67858720

+86-371-67858720 postmaster@zzhxmachine.com

postmaster@zzhxmachine.com sarapang6

sarapang6 +86-137-8347-1727

+86-137-8347-1727